How Commercial Dough Rollers Are Transforming Australian Bakeries and Pizzerias

The Importance of Dough Rollers for Consistency in Your Kitchen

In Australia’s bustling food industry, the quality and consistency of dough directly affect your bottom line. Whether you’re running a popular pizza shop in Sydney’s inner suburbs or managing a boutique bakery in Melbourne’s thriving cafe scene, the challenge remains universal: consistently preparing dough that meets your customers’ expectations without straining your staff or workflow.

Manually rolling dough, while traditional, poses significant operational hurdles. Issues such as inconsistent thickness, uneven baking results, and excessive labour hours can quickly undermine both your reputation and profits. Australian food businesses, big and small, are increasingly recognising the practical benefits of adopting a commercial dough roller to address these challenges effectively.

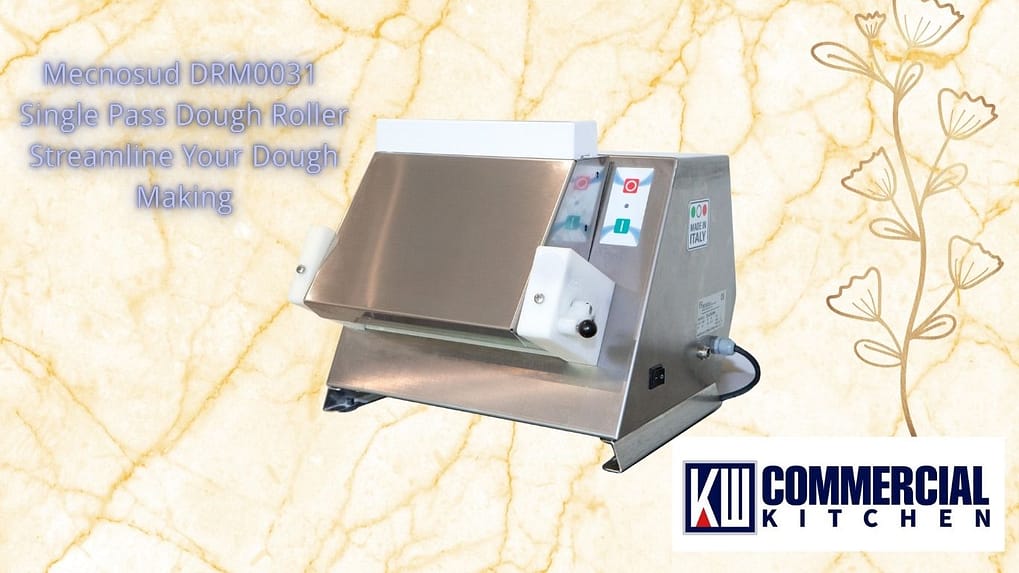

At KW Commercial Kitchen, we’ve partnered with bakeries and pizzerias across Australia for years. We’ve witnessed first-hand how selecting the right dough equipment—like Mecnosud’s robust Italian craftsmanship or Prismafood’s cost-effective, pizza-focused machines—can drastically improve efficiency, consistency, and profitability. Our insights are shaped by practical experiences within real Australian kitchens, not merely technical specifications.

In this guide, you’ll discover clear, actionable advice tailored specifically to Australian bakery and pizzeria operations. We’ll explore how different dough types (pizza, bread, sourdough) influence your equipment choices, discuss critical factors like machine size and roller configurations, and clarify Australian regulatory standards you must consider before investing in commercial dough rollers.

Our goal is straightforward: help you navigate equipment options confidently and ensure you invest in machinery that genuinely supports your business growth. If you’re considering enhancing your kitchen operations, start by exploring curated commercial dough rollers suitable for Australian businesses here: KW Commercial Kitchen Dough Rollers.

When is the Right Time to Invest in a Commercial Dough Roller?

Most bakery and pizzeria owners across Australia start out rolling dough by hand. It’s cost-effective initially, and some customers even appreciate the traditional craftsmanship. However, as your business grows, you quickly realise that relying solely on manual methods has clear limits. The signs become obvious: your team begins struggling to keep pace with increased demand during peak hours, or you notice frequent inconsistencies in your pizza bases or bread thickness. Such discrepancies often lead to uneven baking and customer dissatisfaction.

For example, imagine a local family-run pizzeria in Brisbane. They enjoyed a thriving reputation for handmade pizzas, but as orders climbed beyond 150 pizzas per evening, their staff became overwhelmed, leading to noticeable differences in the thickness and baking quality of the pizzas. This inconsistency resulted in longer wait times and rising complaints, prompting the owners to adopt a compact double-roller dough machine. Within weeks, their issues significantly reduced, restoring consistency and customer satisfaction.

Similarly, a Melbourne-based bakery known for its signature sourdough bread faced production bottlenecks during weekends. Bakers suffered from repetitive strain injuries due to manually handling heavy dough volumes. Introducing a small, precise dough roller not only boosted productivity but also alleviated physical stress, greatly improving employee morale and retention.

If your kitchen is experiencing similar challenges—be it increased volume, inconsistency, or staff fatigue—it’s probably the right moment to consider a commercial dough roller. The long-term benefits far outweigh the initial investment, ensuring smoother operations and satisfied customers.

How Dough Type Influences Your Choice of Dough Roller

One of the critical mistakes many bakery and pizzeria owners make is treating all dough types equally. Dough varies significantly—whether it’s pizza, bread, or sourdough—each type has its own characteristics like hydration levels, gluten structure, and elasticity. Understanding these differences is crucial when selecting the right commercial dough roller.

| Dough Type | Characteristics (Hydration & Elasticity) | Recommended Dough Roller Features | Ideal Usage Examples |

|---|---|---|---|

| Pizza Dough | Moderate hydration (55%-65%); good elasticity and stretch, moderately firm texture. | Double-pass rollers with adjustable thickness; parabolic rollers ideal for edge shaping; non-stick or lightly floured stainless steel rollers recommended. | High-volume pizza shops, pizzerias needing quick, consistent, evenly shaped bases. |

| Bread Dough (Standard) | Medium hydration (60%-70%); elastic but manageable structure, moderate softness. | Straight, robust rollers; wide adjustable thickness range; durable build to handle frequent and varying usage. | Bakeries producing bread loaves, buns, flatbreads, or rolls regularly and in larger quantities. |

| Sourdough (Artisan) | Higher hydration (70%-85%+); delicate gluten structure, very sticky, sensitive to overworking. | Gentle roller action required; non-stick or lightly floured rollers essential; single-pass with adjustable gentle pressure settings preferred. | Artisan bakeries specialising in sourdough, boutique cafés offering handcrafted specialty breads. |

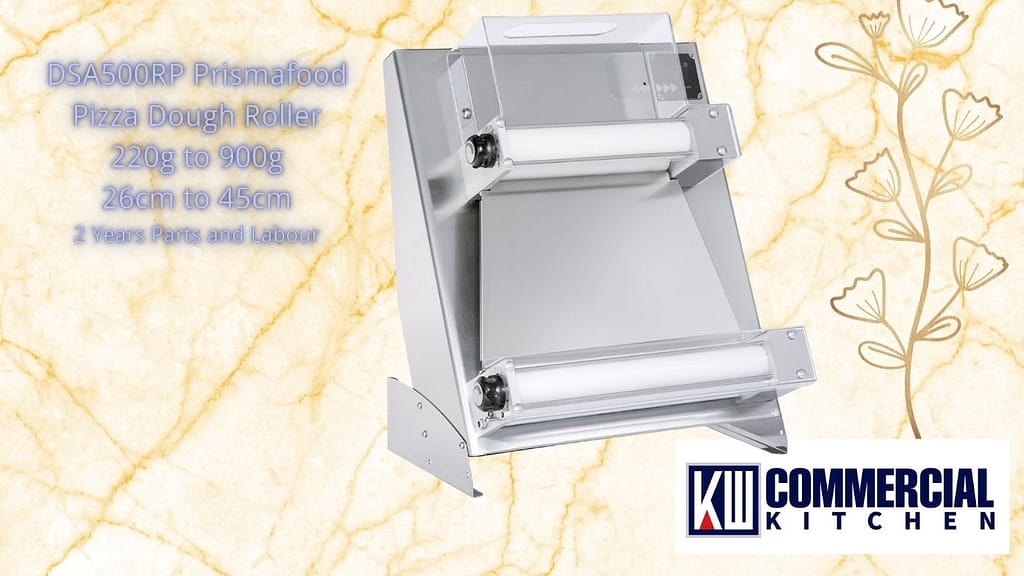

For example, pizza dough typically needs a robust double-pass roller because pizzas require a uniform thickness quickly, especially during busy dinner hours. Rollers with adjustable settings and slightly angled (parabolic) rollers can shape edges, creating that distinctive pizza crust edge effortlessly. Brands like Prismafood are popular among Australian pizzerias due to their practical designs tailored for pizza dough consistency.

Bread dough, used in bakeries producing loaves and rolls, demands flexibility. Medium hydration doughs require straight, sturdy rollers capable of handling continuous usage without sacrificing consistency. Commercial dough rollers from premium manufacturers such as Mecnosud are well-suited for bakeries that need durable, long-term performance.

Artisan sourdough dough, however, presents unique challenges because of its high hydration and delicate gluten structure. These doughs easily tear if handled roughly, necessitating gentle rollers with low pressure settings and effective non-stick surfaces. Here, smaller, precise commercial dough rollers are preferable to protect dough quality.

Clearly understanding the specific characteristics of your dough and choosing equipment accordingly helps ensure consistent, quality results without compromising texture or flavour—a core objective for every successful bakery or pizzeria.

Choosing Between Small and Large Commercial Dough Rollers: What’s Right for Your Kitchen?

Now that you have a clear understanding of how dough types influence roller choices, the next crucial factor is sizing. The physical size of your commercial dough roller isn’t just about how much space it occupies; it’s deeply tied to your daily production requirements, kitchen workflow, and future growth plans. Australian businesses vary significantly—from cosy neighbourhood cafés to large industrial bakeries—each with unique spatial and operational demands.

Small Dough Rollers: Countertop Convenience

Countertop dough rollers are popular among Australian cafés, boutique bakeries, and smaller pizza shops due to their compact footprint and practical efficiency. For instance, imagine a trendy café in Adelaide offering handmade pizzas and pastries daily but constrained by limited kitchen space. A countertop dough roller not only addresses their production bottlenecks but also fits comfortably into their existing workspace without significant modifications.

Pros of Small Dough Rollers:- Space-efficient and easy to position in compact kitchens.

- More affordable initial investment, ideal for budget-conscious businesses.

- Typically easy to install, operate, and maintain.

- Limited production capacity; may struggle during peak demand periods.

- Less suitable for heavy-duty, continuous operation.

- Often fewer advanced features (limited thickness adjustments, simpler configurations).

Large Dough Rollers: Floor-standing Powerhouses

Larger dough rollers—typically floor-standing—are ideal for businesses needing higher volume and consistent output, such as busy Melbourne-based bakeries supplying multiple retail outlets or commercial kitchens handling large catering contracts. For example, consider a high-volume bakery in Sydney’s CBD supplying hundreds of bread loaves daily. A robust, floor-standing dough roller becomes essential equipment, efficiently managing high output demands without compromising consistency or quality.

Pros of Large Dough Rollers:- High production capability, effectively handling large batches continuously.

- Enhanced durability and power, designed for intensive daily use.

- Advanced configurations including dual-roller systems, adjustable precision settings, and sturdy build quality.

- Higher upfront costs, potentially challenging for smaller businesses.

- Significant space requirements; may necessitate kitchen layout adjustments.

- Typically require professional installation and more intensive maintenance.

Selecting the right size comes down to realistically assessing your production needs, available space, and growth ambitions. While smaller machines offer convenience and cost savings, larger models provide scalability, power, and productivity essential for growing establishments.

Single vs. Double Dough Rollers: How to Choose Based on Your Workflow

After deciding on the right size for your dough roller, the next critical factor to consider is whether a single or double roller configuration best fits your kitchen workflow. This choice significantly impacts efficiency, dough handling quality, and overall operational smoothness. Let’s clarify the practical differences clearly.

Single-Pass Dough Rollers: Simple Efficiency

Single-pass dough rollers have one pair of rollers, flattening dough to your desired thickness in a single movement. Ideal for kitchens producing relatively simple or small quantities of products, these rollers typically suit cafés, small bakeries, and boutique pizzerias. For example, a busy café in Perth baking a limited daily batch of pastry dough would find a single roller convenient, reliable, and straightforward.

Benefits of Single-Pass Rollers:- Quick setup and straightforward operation.

- Lower initial cost, making it budget-friendly for smaller businesses.

- Easy to clean and maintain due to fewer moving parts.

Double-Pass Dough Rollers: Enhanced Precision and Volume

Double-pass dough rollers incorporate two sets of rollers arranged sequentially—first flattening the dough, then refining it further, often at a different angle or spacing. Particularly beneficial for pizzerias and bakeries with higher demands for consistency and precision, these machines streamline high-volume workflows effectively. Consider a bustling Sydney pizzeria handling large evening rushes; the precision of a double-pass roller ensures consistently shaped pizza bases at high speeds, significantly reducing preparation bottlenecks.

Advantages of Double-Pass Rollers:- Superior dough consistency and precise thickness control.

- Efficient handling of larger production volumes.

- Ideal for achieving uniform, professional dough shapes, especially pizzas.

Ultimately, the decision comes down to your production volume, required precision, and operational complexity. Small-scale, simplicity-driven kitchens benefit from single-pass rollers, while larger establishments prioritising consistency and productivity typically see greater advantages from double-pass machines.

Comparing Dough Roller Brands: Mecnosud, Prismafood, and Beyond

When investing in commercial dough rollers, choosing a trusted brand is as crucial as understanding the machine’s functionality. In Australia, several reputable brands have consistently proven themselves reliable. Each brand caters differently to bakery and pizzeria needs, ranging from premium artisan equipment to cost-effective, pizza-focused machines.

| Brand | Country of Origin | Best For | Key Strengths | Typical Users in Australia |

|---|---|---|---|---|

| Mecnosud | Italy | Premium bakery equipment, artisan bread, high-volume pastry production | Exceptional durability, precise thickness control, versatile configurations, reliable performance under heavy daily use | High-end bakeries, artisan cafés, established pastry kitchens (e.g., Melbourne’s artisan bread specialists) |

| Prismafood | Italy | Pizza-specific operations, mid-range affordability, medium-high volume | Cost-effective design, pizza dough specialty, user-friendly operations, reliable consistency at an accessible price | Pizzerias, pizza-focused cafes and restaurants (e.g., Sydney and Brisbane-based pizza chains) |

| Moretti Forni | Italy | High-end pizza production, gourmet kitchens | Precision engineering, consistent thickness accuracy, advanced features for specialty dough handling | Gourmet pizzerias, specialty bakeries needing advanced dough handling precision |

| Anvil | South Africa | Entry-level to mid-range bakeries and cafes | Affordable entry point, straightforward operations, suitable for moderate daily usage | Small bakeries, cafés, and catering businesses across regional areas (e.g., cafés in Perth or regional Queensland) |

At KW Commercial Kitchen, we focus on curating commercial dough roller options specifically tailored to Australian businesses. Rather than overwhelming you with every available brand, we carefully select models based on consistent performance, reliability, and suitability to typical Australian bakery and pizzeria workflows. For instance, Mecnosud is a frequent recommendation for artisan bakeries needing durable, versatile machines, while Prismafood often suits businesses aiming for affordable yet efficient pizza production.

Our approach isn’t about simply supplying equipment. We actively partner with our clients, ensuring each recommendation genuinely aligns with their specific operational needs, space considerations, and budget realities. This curated approach saves our clients time, reduces operational risks, and ensures they gain maximum value from their investment.

Important Dough Roller Features: What Matters Most in Daily Operations?

Choosing a reputable brand such as Mecnosud or Prismafood is essential, but the brand alone doesn’t guarantee a perfect fit for your kitchen. To genuinely benefit from a commercial dough roller, carefully assess practical features that directly impact your daily operations. From precise thickness control to ease of cleaning, durability, and safety—each aspect influences your workflow efficiency and overall satisfaction.

1. Adjustable Dough Thickness Controls

Precision in dough thickness directly affects baking quality and customer satisfaction. Machines that offer clearly marked, easily adjustable thickness settings ensure consistent product quality every day. For example, a bakery in Canberra producing artisan pastries daily would significantly benefit from quick, repeatable thickness adjustments, improving product uniformity and reducing waste from inconsistent baking.

2. Easy Cleaning and Maintenance

Dough preparation is inherently messy, and cleaning becomes a critical daily routine. Look for dough rollers designed with easily removable rollers, scrapers, or food-grade covers to simplify your end-of-day cleaning. A compact Melbourne café using a countertop roller saves valuable staff time each evening by easily accessing removable components, keeping hygiene standards consistently high and compliance effortless.

3. Material and Build Durability

Durability ensures your investment remains cost-effective over the long term. Commercial dough rollers constructed from robust stainless steel or corrosion-resistant materials withstand heavy daily use typical in busy Australian kitchens. Imagine a high-volume Sydney pizzeria operating seven days a week; durable equipment significantly reduces downtime and repair costs, directly protecting profitability.

4. Safety Features and User Protection

Safety in commercial kitchens is non-negotiable. Ensure your dough roller includes essential protective features like emergency stop buttons, automatic safety guards, and overload protection. For instance, a bustling bakery in Brisbane operating multiple shifts appreciates integrated safety features that reduce accident risk, enhancing employee confidence and operational continuity.

5. Roller Width and Output Configuration

Carefully consider roller width and dough output paths to ensure seamless integration into your kitchen’s workflow. Machines offering adjustable width or convenient front or side dough collection help streamline production and avoid workflow bottlenecks, particularly beneficial for operations dealing with varied dough sizes or shapes.

Ultimately, selecting a dough roller equipped with these practical features ensures smooth daily operation, consistent product quality, and a safe working environment. Assess your specific kitchen needs carefully, keeping these considerations in mind to make a purchase that delivers lasting value and reliability.

Compliance and Safety: Australian Standards for Commercial Dough Rollers

Running a bakery or pizzeria in Australia isn’t only about making delicious products—it’s equally critical to ensure compliance with official regulations. Understanding these requirements directly impacts your business legally, financially, and operationally.

Food Safety Standards (FSANZ)

The Australian government mandates stringent food safety regulations through the Food Standards Code developed by Food Standards Australia New Zealand (FSANZ). Specifically, Standard 3.2.3 (Food Premises and Equipment) requires all commercial kitchen equipment—including dough rollers—to be made from smooth, corrosion-resistant, and easily cleanable food-safe materials. Ensuring compliance helps prevent contamination risks and safeguards your business from hefty fines or closure.

Electrical Safety Requirements (AS/NZS Standards)

Australian commercial kitchen equipment must comply with electrical safety standards outlined in AS/NZS 3820:2020 – Essential Safety Requirements for Electrical Equipment. Non-compliant dough rollers pose risks such as electrical faults, fire hazards, or accidents—potentially causing significant legal and operational disruptions.

Work Health and Safety (WHS) Regulations

Under Australia’s Model Work Health and Safety (WHS) laws, employers must ensure safe working environments. Dough rollers must feature mandatory safety mechanisms—such as emergency stops, safety guards, and clear operational instructions—to reduce workplace accidents and comply with legal obligations. Adhering to WHS regulations protects your employees and shields your business from substantial penalties and liability claims.

By sourcing equipment through knowledgeable Australian suppliers like KW Commercial Kitchen, you’re assured compliance with all relevant standards. This not only secures your legal standing but also significantly supports your business reputation and long-term sustainability.

Practical Maintenance to Maximise the Lifespan of Your Commercial Dough Roller

While ensuring compliance with Australian standards protects your business legally, maintaining your dough roller regularly protects your investment practically and financially. Routine maintenance reduces equipment downtime, prevents costly repairs, and significantly prolongs the operational life of your machine.

Daily Maintenance: Quick Cleaning Routine

- Step 1: After daily use, turn off and unplug the dough roller for safety.

- Step 2: Carefully remove any excess dough or flour residue using a soft brush or plastic scraper.

- Step 3: Wipe rollers and exposed surfaces with a damp cloth dipped in mild food-grade detergent solution.

- Step 4: Dry thoroughly using a clean, lint-free towel to prevent moisture-related corrosion.

A brief daily cleaning significantly reduces buildup, ensuring hygiene standards and smoother operations the next day.

Weekly Maintenance: Detailed Cleaning and Inspection

- Step 1: Disconnect power supply completely for safe inspection.

- Step 2: Remove and thoroughly clean roller scrapers or guards using warm, soapy water.

- Step 3: Inspect rollers and moving parts closely for any signs of wear or damage.

- Step 4: Lubricate bearings or moving parts lightly (if recommended by manufacturer).

Weekly checks help detect minor issues early, preventing costly breakdowns during peak production times.

Monthly Maintenance: Comprehensive Equipment Check

- Step 1: Conduct a thorough check of electrical components, including cords and plugs, for visible damage or wear.

- Step 2: Test safety features (emergency stops, safety guards) to ensure proper functionality.

- Step 3: If applicable, schedule professional maintenance annually or biannually for complex repairs or detailed servicing.

Consistent monthly checks ensure compliance with Australian safety regulations, avoiding downtime and substantial repair costs.

Regular maintenance not only extends your dough roller’s lifespan but directly translates to significant long-term savings, operational efficiency, and consistent product quality. Protecting your equipment proactively means protecting your bottom line.

Real-Life Australian Scenarios: Selecting the Right Dough Roller for Your Business

Choosing a dough roller isn’t a one-size-fits-all decision. To help you visualise practical benefits, here are three genuine scenarios of typical Australian businesses—each highlighting how different machines match distinct operational needs.

Scenario 1: Compact Pizzeria (Prismafood Dough Roller)

Imagine “Bella Pizza,” a small but popular neighbourhood pizzeria in Melbourne’s suburbs. They serve around 100 pizzas nightly. Space is limited, and speed matters. A Prismafood double-pass dough roller offers Bella Pizza a perfect fit: compact enough for tight kitchen spaces, affordable enough for smaller budgets, yet reliable enough to ensure consistent, evenly shaped pizza bases during their busy evening hours. The practical benefit? Faster service times, reduced staff stress, and improved customer satisfaction without significant upfront costs.

Scenario 2: Artisan Bakery and Café (Mecnosud Dough Roller)

Now consider “Crust & Crumb,” an artisan bakery and café located in Sydney’s inner-west, famous for handmade sourdough breads and specialty pastries. They deal with sensitive dough types needing gentle handling to preserve texture. A premium Mecnosud dough roller suits their needs precisely—built robustly with highly adjustable thickness settings, gentle roller action, and durability designed for high-volume daily usage. Practically, it helps the bakery maintain artisanal quality consistently, reduces dough wastage significantly, and allows bakers more time to focus on creative product development instead of repetitive dough handling.

Scenario 3: Growing Catering Company (Mid-sized Floor Model)

Finally, take “Gourmet Gatherings,” a growing Brisbane catering company providing breads, flatbreads, and mini pizzas for corporate events and weddings. As demand grows rapidly, manually rolling dough becomes unsustainable. They require a versatile, mid-sized floor-standing dough roller, offering high output and reliable performance without occupying excessive space. Choosing a practical and robust mid-sized model ensures streamlined dough production, consistent product quality, and enhanced operational efficiency, directly supporting their continued growth without overwhelming initial investment.

Each of these scenarios clearly illustrates the practical advantages and tangible operational impacts of matching a dough roller precisely to your business requirements, workflow, and future ambitions.

Calculating Your Dough Roller Investment: Understanding ROI and Cost Efficiency

After exploring practical business scenarios, it’s essential to evaluate your investment clearly through a financial lens. Understanding the return on investment (ROI) of a commercial dough roller involves assessing labour savings, production improvements, and enhanced product consistency, ensuring your business decision is financially sound.

1. Labour Cost Savings

Calculate current staff hours dedicated to manual dough preparation weekly. For example, if your Melbourne bakery spends 20 hours weekly rolling dough manually at an average wage of $25/hour, that’s $500 per week. By investing in a dough roller, you could significantly reduce this to around 5 hours weekly, saving $375 per week or nearly $20,000 annually—quickly justifying initial equipment costs.

2. Increased Production and Sales Potential

Efficient dough rollers considerably increase your kitchen’s output capacity. If your Sydney pizzeria currently produces 100 pizzas nightly, a dough roller might allow you to comfortably handle an additional 30 pizzas per night. At an average profit margin of $8 per pizza, that’s an extra $240 daily or potentially $60,000+ annually.

3. Consistency and Reduced Wastage

Manual dough rolling often results in inconsistent thickness, causing uneven baking and unnecessary dough wastage. Dough rollers enhance consistency, directly reducing ingredient waste. If you previously lost 5% of dough daily through manual errors, consistent rolling could cut this down significantly—improving your ingredient cost efficiency notably over the year.

Clearly assessing these practical financial factors—labour savings, increased output, and reduced waste—demonstrates how quickly a commercial dough roller investment can pay for itself, significantly boosting your bakery or pizzeria’s overall profitability.

Common Questions Australian Businesses Have about Commercial Dough Rollers

What’s the real difference between a dough roller and a dough sheeter—which one do I actually need?

A dough roller quickly flattens dough balls into consistent shapes—excellent for pizzas, flatbreads, or initial dough preparation. A dough sheeter stretches dough into thin, uniform sheets using conveyor belts, essential for laminated doughs like croissants or puff pastry. If your business primarily makes pizzas or basic breads, a dough roller suits your needs best. Artisan pastry kitchens typically prefer sheeters.

Is a commercial dough roller suitable for gluten-free dough?

Yes, but gluten-free dough can behave differently because it’s stickier and less elastic. Choose dough rollers with non-stick surfaces or dust rollers lightly with gluten-free flour like rice or potato starch. Australian bakeries regularly handling gluten-free dough find gentle pressure settings and careful adjustments essential to prevent tearing.

Will using a dough roller negatively affect dough quality or texture?

Not if used correctly. Dough rollers can potentially overwork dough if repeatedly passed through rollers too tightly or aggressively. The key is gradual adjustment and minimal passes to reach the desired thickness. High-quality machines like Mecnosud allow precise adjustments, protecting dough texture and ensuring consistent quality.

How long does a commercial dough roller typically last in an Australian kitchen?

On average, commercial dough rollers last around 10 to 15 years or more, depending significantly on usage intensity, maintenance, and initial equipment quality. Regular daily cleaning, weekly inspections, and proper annual servicing dramatically extend equipment life, ensuring consistent performance and reducing downtime.

Are commercial dough rollers hard to clean?

Quality dough rollers designed for commercial use are generally straightforward to clean. Machines with easily removable rollers, scrapers, and accessible parts streamline cleaning significantly. Establishments across Australia, from busy Sydney pizzerias to Melbourne bakeries, commonly look for rollers specifically marketed as easy-clean models to save labour time and maintain hygiene standards efficiently.

Do I need professional installation for a commercial dough roller?

This depends on the roller size and electrical requirements. Compact countertop dough rollers typically require simple installation and standard power outlets. Larger floor-standing machines usually need professional installation to ensure proper electrical connections and operational safety compliance according to Australian electrical standards.

What are the legal requirements I need to consider when buying a dough roller in Australia?

Australian businesses must ensure commercial dough rollers meet FSANZ Standard 3.2.3 (Food Equipment), AS/NZS 3820 electrical safety standards, and Work Health and Safety (WHS) laws. Buying from reputable Australian suppliers such as KW Commercial Kitchen ensures your equipment fully complies, protecting your business legally and operationally.

How can I know if investing in a dough roller is financially worthwhile?

Evaluate current labour costs spent on manual dough preparation weekly, estimate potential increases in production, and factor in savings from reduced dough wastage. Generally, bakeries and pizzerias across Australia find a dough roller investment pays for itself within 12-18 months due to labour savings and increased production efficiency.

Choosing the Ideal Commercial Dough Roller for Sustainable Success

Selecting the right commercial dough roller is essential for the long-term success of your bakery, café, or pizzeria in Australia. Your decision should be informed by key practical considerations we’ve discussed, such as equipment size (countertop versus floor-standing), roller configurations (single or double-pass), dough compatibility (pizza, bread, sourdough), trusted brand reputation (such as Mecnosud and Prismafood), and critical compliance with Australian FSANZ, electrical, and WHS standards.

More than simply a purchase, your dough roller represents a strategic investment. It directly impacts your workflow efficiency, product consistency, labour savings, customer satisfaction, and overall profitability. Understanding these practical considerations ensures that your choice genuinely supports your operational needs and future growth, rather than merely filling an equipment gap.

At KW Commercial Kitchen, our role goes beyond equipment supply. With extensive experience supporting Australian bakeries, pizzerias, and food businesses, we act as trusted advisors. Our approach prioritises practical, tailored guidance—understanding your unique operational requirements, budget, and production ambitions before recommending equipment. We aim to ensure you make informed, confident decisions that drive sustainable success, not quick sales.

Whether you’re scaling up production, upgrading from manual dough preparation, or refining your product quality, we encourage you to reflect on your business’s current needs and long-term goals carefully. Evaluate your choices practically, seek professional advice where needed, and choose a dough roller that genuinely aligns with your ambitions.

Invest thoughtfully, partner wisely, and your dough roller will become more than equipment—it will become a cornerstone of your sustainable business success.