The Ultimate Guide to Commercial Blast Chillers in Australia: Benefits, Technology, Compliance & Trends

Introduction: Why Commercial Blast Chillers Are Essential for Australian Food Businesses

Operating a successful restaurant, café, or commercial kitchen in Australia’s highly competitive hospitality industry demands exceptional efficiency, meticulous food safety compliance, and precise cost management. With food safety regulations set by Food Standards Australia New Zealand (FSANZ) becoming increasingly stringent, businesses face continuous pressure to minimise food waste, ensure impeccable hygiene, and maintain consistently high food quality.

In this challenging landscape, commercial blast chillers in Australia have emerged as indispensable equipment for savvy food operators. Unlike traditional refrigeration methods, blast chillers rapidly cool freshly cooked foods from unsafe temperatures of around 70°C down to safe storage temperatures below 3°C in under 90 minutes. This rapid chilling not only significantly reduces harmful bacterial growth but also preserves the food’s texture, taste, and nutritional value, ensuring your dishes remain appealing and compliant with Australian food safety standards.

Moreover, commercial blast chillers dramatically boost kitchen efficiency, allowing for bulk meal preparation, reducing food spoilage, and cutting overall operational costs. Investing in this innovative technology has already become standard practice for many successful food establishments across Sydney, Melbourne, Brisbane, and beyond, providing them with a clear competitive advantage.

In this comprehensive guide, we’ll explore precisely why a commercial blast chiller in Australia is not just beneficial—but essential—for your business. From understanding their advanced technology and ensuring compliance with FSANZ regulations, to real-life success stories and future trends, you’ll discover everything you need to maximise productivity, improve profitability, and elevate your culinary operations in Australia’s vibrant food scene.

What is a Blast Chiller? Understanding Quick Chilling Technology in Commercial Kitchens

A blast chiller is a specialised commercial refrigeration unit designed specifically to rapidly reduce the temperature of hot or freshly cooked food, bringing it swiftly down from around 70°C to below 3°C in under 90 minutes. This process, known as quick chilling technology, significantly limits bacterial growth and ensures food safety compliance in busy Australian commercial kitchens.

The Science Behind Blast Chilling vs Standard Refrigeration

Unlike standard refrigeration or traditional freezers—which are engineered to maintain already cold or frozen foods—blast chillers operate by forcibly circulating cold air at high velocities around food items. The powerful airflow generated by robust compressors and fans quickly removes heat, cooling foods evenly from the outside to the core. This contrasts sharply with regular refrigeration, which passively cools food, often taking 4 to 6 hours to reach the same safe storage temperature.

Key Technical Differences:

| Feature | Commercial Blast Chiller | Standard Refrigerator | Standard Freezer |

|---|---|---|---|

| Cooling Method | Forced, high-velocity cold air | Passive cold airflow | Slow freezing via static cold air |

| Typical Cooling Speed | 70°C to 3°C in under 90 mins | 4-6 hours to cool same volume | 8+ hours to fully freeze |

| Bacterial Growth Risk | Very low (rapid through danger zone) | Moderate (slow through danger zone) | Moderate (risk of freezer burn) |

| Food Quality Preservation | Excellent (texture, taste preserved) | Good (but slower cooling reduces quality) | Fair (slow freezing affects texture) |

Typical Operating Parameters of Commercial Blast Chillers

Commercial blast chillers typically operate within precise temperature and time parameters to comply with Australian food safety standards (FSANZ). A standard blast chiller cycle rapidly cools cooked food from a minimum of 70°C down to under 3°C within a strict 90-minute window. Advanced units may feature intelligent chilling systems that automatically adjust cooling parameters based on food quantity, weight, and consistency, optimising food quality and safety.

Ultimately, understanding the fundamental differences between blast chilling vs standard refrigeration highlights the critical role blast chillers play in maintaining impeccable food safety, superior quality, and unmatched operational efficiency in Australia’s competitive hospitality sector.

How Does a Blast Chiller Work? Technical Deep Dive into Blast Chiller Technology Australia

Commercial blast chillers utilise advanced forced air chilling technology to rapidly and evenly cool food. At the heart of this technology is a high-powered airflow system, combined with precision temperature control, ensuring food is swiftly chilled through the critical “danger zone” where harmful bacteria thrive.

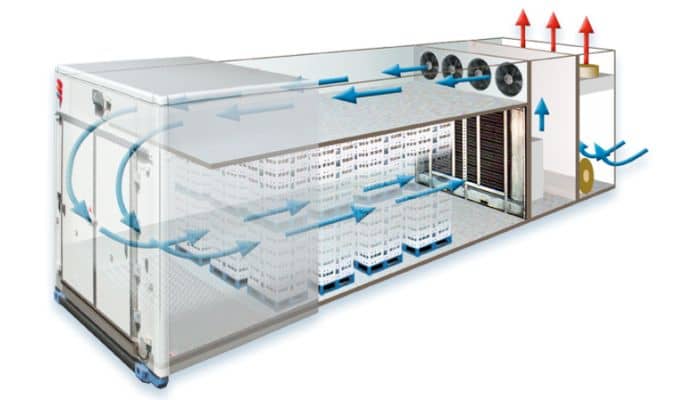

The Core Cooling Principle: High-Efficiency Forced Air Circulation

The blast chiller works by circulating extremely cold air around hot food at high speeds. This rapid airflow quickly removes heat from food surfaces, cooling the food efficiently and uniformly from the outside to the centre. Unlike standard refrigeration methods, which rely on passive cooling, blast chillers actively and aggressively cool food, significantly reducing the time food spends in bacterial growth zones.

Key Components of Commercial Blast Chillers Explained

- Evaporator Coils: Act as the lungs of the chiller, absorbing heat from inside and rapidly cooling the air.

- Compressor: The heart of the cooling system, compressing refrigerant gas and raising its pressure and temperature, enabling efficient heat transfer.

- Condenser Unit: Located externally, dissipating heat drawn from food into the outside environment and returning refrigerant to its liquid state.

- Fans & Air Distribution System: Powerful fans circulate cold air evenly and rapidly within the chiller, ensuring uniform cooling throughout.

Advanced Intelligent Temperature Control Technology

Modern blast chillers in Australia are equipped with sophisticated temperature monitoring systems, including precise sensors and food probes. These components provide real-time data on food core temperature, allowing the chiller to intelligently adapt cooling cycles based on the size, weight, and type of food. This self-adjusting feature—known as intelligent temperature control—optimises cooling efficiency, food safety, and energy consumption.

By combining these advanced components and technologies, commercial blast chillers ensure consistently safe, high-quality, and efficiently managed food preparation in Australian commercial kitchens.

Why Australian Restaurants Need Blast Chillers

Food Safety and Regulatory Compliance

In Australia, maintaining food safety is paramount for all food businesses. The Food Standards Australia New Zealand (FSANZ) Standard 3.2.2 mandates that potentially hazardous foods must be cooled from 60°C to 21°C within two hours and from 21°C to 5°C within a further four hours. Blast chillers are specifically designed to achieve this rapid cooling, ensuring compliance with these strict guidelines and minimizing the risk of bacterial growth.

Enhancing Food Quality

Rapid cooling not only ensures safety but also preserves the quality of food. By quickly reducing the temperature, blast chillers help maintain the texture, flavor, and nutritional value of dishes. For instance, high-end Australian restaurants have reported that using blast chillers allows them to prepare dishes in advance without compromising on quality, leading to more consistent and efficient service.

Commercial Cost Efficiency

Food waste is a significant issue in Australia, with an estimated 7.6 million tonnes of food wasted annually, costing the economy approximately $36.6 billion each year. Implementing blast chillers in commercial kitchens can substantially reduce food spoilage by extending shelf life and allowing for better inventory management. According to the 2024 Impact Report by End Food Waste Australia, businesses that adopted advanced food preservation methods, including blast chilling, saw a 13% reduction in food waste between 2022 and 2024, translating to significant cost savings.

Core Benefits of Blast Chillers for Australian Commercial Kitchens

Extended Shelf Life and Reduced Food Waste

One of the primary benefits of blast chillers in Australia is their ability to dramatically extend the shelf life of food items. By rapidly reducing food temperatures to safe levels, blast chillers inhibit bacterial growth and significantly reduce spoilage, playing a critical role in reducing commercial food waste. Businesses can buy produce in bulk or during peak season, safely storing items longer without compromising quality, which translates into noticeable cost savings and reduced waste.

Improved Food Safety Compliance

Ensuring rapid cooling of hot foods is essential to meet Australian food safety standards. Blast chillers quickly move food through the bacterial danger zone (60°C to 5°C), reducing contamination risk and ensuring compliance with FSANZ requirements. As a result, businesses benefit from fewer food safety concerns and improved health inspection outcomes.

Enhanced Texture, Taste, and Nutritional Value

Unlike conventional refrigeration methods, blast chillers preserve food quality by preventing the formation of large ice crystals, which can damage food texture and nutrients. Food items retain their original taste, texture, appearance, and nutritional integrity, allowing Australian restaurants to consistently deliver dishes that exceed customer expectations.

Increased Kitchen Efficiency and Reduced Labour Costs

Blast chillers significantly streamline kitchen workflow by allowing chefs to prepare dishes in bulk, rapidly chill them, and store for later use. This reduces daily preparation time, decreases labour costs, and enhances overall operational efficiency. Restaurants can serve dishes faster without sacrificing quality, thereby boosting productivity and profitability.

Energy Efficiency and Long-term Cost Savings

While blast chillers require an initial investment, their rapid cooling capability ultimately lowers long-term operational costs. Quick chilling reduces energy usage compared to traditional refrigeration, which works harder and longer to achieve the same results. Over time, this energy efficiency not only helps reduce your carbon footprint but also translates into substantial utility bill savings, further enhancing your restaurant’s bottom line.

How Blast Chillers Save Money for Australian Restaurants

Extended Ingredient Shelf Life

Blast chillers quickly cool food, significantly extending the shelf life of ingredients. By swiftly reducing temperatures from hot to safe storage levels, restaurants can dramatically reduce spoilage, maximising their ingredient investment. Faster cooling translates directly into decreased food losses, enhancing your profit margins.

Seasonal Bulk Purchasing

Restaurants using blast chillers benefit from purchasing ingredients in bulk during peak seasons when prices are lowest. Thanks to rapid chilling, large quantities of fresh, seasonal produce can be safely stored for extended periods without quality degradation. This strategy provides considerable long-term cost savings, ensuring premium quality ingredients year-round at lower prices.

Reduction in Food Waste

Food wastage is a significant cost burden in Australian kitchens. Blast chillers dramatically reduce waste by preventing common spoilage issues associated with traditional refrigeration methods. According to the latest data from End Food Waste Australia’s 2024 Impact Report, restaurants using rapid chilling techniques achieved up to 13% reductions in annual food waste.

Improved Operational Efficiency

Blast chillers optimise kitchen workflows, allowing chefs to prepare large batches of food efficiently. Food items can be chilled immediately after cooking, streamlining daily operations and significantly reducing preparation time during busy service periods. This improvement in kitchen workflow directly cuts down labour requirements, resulting in lower staffing costs and greater operational efficiency.

Energy and Maintenance Cost Savings

Blast chillers consume energy more efficiently by cooling food rapidly within a short timeframe, rather than running continuously like conventional refrigeration systems. Reduced operating hours not only lower energy bills but also minimise wear and tear on equipment, leading to less frequent maintenance and longer equipment lifespan.

Cost Efficiency Comparison Table: Traditional Refrigeration vs Blast Chillers

| Cost Factor | Traditional Refrigeration | Blast Chiller |

|---|---|---|

| Cooling Time (70°C to 3°C) | 4–6 hours | Under 90 mins |

| Food Waste Reduction | Minimal | Up to 13% |

| Bulk Purchase Savings | Limited | Significant (Seasonal) |

| Energy Consumption | High (continuous) | Low (short burst) |

| Maintenance Frequency | Higher (continuous wear) | Lower (efficient use) |

For example, a renowned Melbourne restaurant reported a 20% reduction in monthly operating costs after adopting blast chillers, clearly illustrating how blast chillers save money in Australian commercial kitchens. The combination of lower food waste, reduced labour, and decreased energy consumption contributed to these significant savings.

Commercial Kitchen Case Study Australia: How a North Sydney Wagyu BBQ Restaurant Improved Efficiency with a Blast Chiller

Background: Premium Japanese Wagyu BBQ in North Sydney

Located in the bustling culinary hub of North Sydney, a renowned Japanese Wagyu BBQ restaurant faced challenges common to high-end dining establishments: maintaining premium ingredient freshness, controlling rising operational costs, and consistently delivering impeccable food quality. With Wagyu beef and specialty ingredients commanding premium prices, minimising waste was essential.

Solution: Integrating the Everlasting BCE2020 Blast Chiller

Seeking an effective solution, the restaurant invested in the Everlasting BCE2020 Blast Chiller. This high-performance blast chiller enabled rapid cooling of cooked and raw foods, preserving freshness, flavour, and texture while ensuring full compliance with Australian food safety regulations.

Quantifiable Results and Operational Improvements

- Reduced Food Waste: After implementation, the restaurant reported a significant 4% reduction in food costs due to decreased ingredient wastage. Given the high cost of premium Japanese ingredients, this translated into savings exceeding AUD $1,000 per week.

- Improved Operational Efficiency: Kitchen workflow efficiency improved by approximately 30%, as staff could batch-prepare menu items in advance and rapidly chill them without compromising on quality.

- Enhanced Customer Satisfaction: Customer feedback showed notable improvement, with satisfaction ratings increasing by nearly 20%, particularly regarding freshness and flavour consistency of their signature Wagyu dishes.

Testimonials from the Team

Head Chef Takeshi Tanaka shared his personal experience: “Implementing the Everlasting Blast Chiller transformed our kitchen operations. We’re preserving the integrity and quality of our premium Wagyu beef like never before, resulting in dishes that truly delight our customers.”

Restaurant Manager, Emma Wilson, noted the business impact: “Not only has food quality improved significantly, but we’ve also dramatically reduced waste. Saving over a thousand dollars weekly is substantial—especially when working with high-value ingredients. This investment has clearly paid for itself.”

This blast chiller success story in Australia underscores how thoughtful investment in kitchen equipment can lead to tangible financial and qualitative gains in the competitive restaurant industry.

The Ultimate Guide to Commercial Blast Chillers in Australia: Benefits, Technology, Compliance & Trends

Introduction

In Australia’s competitive hospitality industry, ensuring food safety, maintaining quality, and optimizing kitchen efficiency are paramount. Commercial blast chillers have emerged as essential equipment in modern kitchens, addressing these challenges effectively. This guide explores the benefits, technology, compliance requirements, and trends associated with commercial blast chillers in Australia.

What is a Blast Chiller?

A blast chiller is a specialized refrigeration unit designed to rapidly reduce the temperature of cooked food, minimizing bacterial growth and preserving food quality. Unlike standard refrigeration, blast chillers can bring food temperatures down from 70°C to 3°C within 90 minutes, ensuring compliance with food safety standards.

- Cooling Speed: Rapid temperature reduction to prevent bacterial growth.

- Technology: Utilizes high-velocity forced air circulation for uniform cooling.

- Food Quality: Maintains texture, flavor, and nutritional value better than slow cooling methods.

How Does a Blast Chiller Work?

Blast chillers operate through advanced components and technologies:

- Evaporator Coils: Absorb heat from the food, initiating cooling.

- Compressor: Circulates refrigerant, facilitating efficient heat exchange.

- Condenser Unit: Releases heat outside the unit.

- Fans and Air Distribution: Ensure uniform cooling with forced air.

Modern blast chillers feature intelligent temperature control systems with sensors and probes, automatically optimizing performance.

Figure: Blast Chiller Operational Workflow

Why Do Australian Restaurants Need a Blast Chiller?

Food Safety and Regulatory Compliance

The Food Standards Australia New Zealand (FSANZ) Standard 3.2.2 mandates rapid cooling for food safety. Blast chillers enable easy compliance by quickly lowering temperatures.

Enhanced Food Quality

Rapid cooling preserves texture, flavor, and nutrients, enhancing customer satisfaction in premium Australian restaurants.

Operational Cost Savings

Blast chillers reduce spoilage, significantly cutting operational costs. The Australian government reports annual food waste costing $36.6 billion, highlighting blast chillers’ potential to save substantially.

Core Advantages of Blast Chillers

- Extended Shelf Life

- Improved Food Safety

- Enhanced Food Quality

- Operational Efficiency

- Energy Efficiency

Case Study: Japanese Wagyu BBQ in North Sydney

A renowned Wagyu restaurant integrated the Everlasting BCE2020 Blast Chiller, reducing food costs by 4%, saving over AUD $1,000 weekly, and enhancing customer satisfaction significantly.

Blast Chiller Future Trends Australia: IoT and Sustainable Refrigeration Technology

Integration of IoT Refrigeration Technology Australia

The Australian commercial refrigeration industry is increasingly adopting Internet of Things (IoT) technology. IoT-enabled blast chillers offer real-time temperature monitoring, remote control, predictive maintenance alerts, and compliance tracking capabilities. These intelligent features enhance operational efficiency, streamline food safety compliance, and significantly reduce downtime for hospitality businesses.

Sustainable and Energy-Efficient Refrigeration

Environmentally friendly refrigeration technologies, such as natural refrigerants like R290 (Propane), are becoming standard practice in Australia. Blast chillers leveraging these sustainable refrigerants help businesses meet growing regulatory demands for reduced greenhouse gas emissions and energy-efficient operations, resulting in lower operational costs and improved sustainability credentials.

Rising Demand for Blast Chillers in Australian Hospitality

With increasing consumer demand for high-quality dining experiences and stringent food safety standards, the demand for blast chillers in Australia’s hospitality sector is forecasted to grow significantly. Industry analysts predict that by 2028, market penetration of blast chillers in commercial kitchens across Australia could rise by over 15%, driven by an emphasis on efficiency, reduced food waste, and enhanced food safety.

These combined advancements position blast chillers as indispensable tools for future-ready Australian restaurants, catering to evolving consumer expectations and regulatory requirements.

Frequently Asked Questions (FAQ)

What are FSANZ’s specific regulations regarding rapid food cooling?

According to FSANZ Standard 3.2.2, potentially hazardous foods must be cooled from 60°C to 21°C within two hours, and further reduced from 21°C to 5°C within an additional four hours. Blast chillers facilitate compliance by achieving these cooling requirements rapidly and consistently.

Does my restaurant truly need a blast chiller?

If your restaurant handles significant volumes of cooked or perishable food, aims for superior food quality, and must comply strictly with Australian food safety standards, a blast chiller is highly recommended. It significantly reduces food waste, improves operational efficiency, and ensures regulatory compliance.

Are blast chillers expensive to operate daily?

Although blast chillers require an initial investment, their daily operational costs are relatively low. Rapid chilling reduces energy use compared to continuous operation of standard refrigeration units. Additionally, savings from reduced food spoilage and efficient workflow typically offset these running costs quickly.

What are common maintenance issues with blast chillers?

Common maintenance issues include blocked condenser coils, worn door seals, sensor inaccuracies, and occasional refrigerant leaks. Regular cleaning, preventive maintenance checks, and prompt service from professional technicians will help mitigate these problems, ensuring reliable long-term performance.

Conclusion & Actionable Recommendations

In Australia’s competitive foodservice industry, investing in a commercial blast chiller is no longer just beneficial—it’s essential. Blast chillers significantly improve food safety, quality, operational efficiency, and sustainability, directly contributing to reduced costs and increased customer satisfaction. To ensure compliance and maximise your kitchen’s productivity, selecting the right blast chiller tailored to your specific needs is crucial.

Before making your decision, review the official guidelines from FSANZ Standard 3.2.2 and insights from the latest National Food Waste Assessment.

Ready to choose the perfect blast chiller for your Australian kitchen? Explore our extensive range of reliable, efficient, and advanced KW Commercial Blast Chillers.

Need Expert Guidance?

Contact our dedicated refrigeration specialists today for tailored advice: Contact KW Commercial