The Secret to Keeping Chips Crispy: Why Every Kitchen Needs the Right Chip Warmers

There’s nothing quite like biting into a perfectly crisp, piping-hot chip—especially in Australia’s chilly winter months, when customers crave warmth and comfort. Yet too often, kitchens struggle to deliver this simple pleasure consistently. Soggy chips not only disappoint customers; they directly impact your restaurant’s bottom line. One dissatisfied customer quickly translates into lost repeat business and negative word-of-mouth.

Investing in reliable chip warmers is essential for maintaining food quality and customer satisfaction.

But soggy chips and lost sales aren’t inevitable. The solution lies in strategically choosing the right commercial warming equipment. In busy periods, a high-quality chip warmer speeds up service, helps manage rush-hour demands, and keeps your queues moving smoothly. During quieter times, energy-efficient warming solutions reduce electricity and gas consumption, significantly lowering your monthly utility bills.

Whether you’re managing a bustling takeaway, a cosy café, or a high-volume food court, the type of warmer you choose—be it a simple chip warmer, an advanced heated display case, or a fully integrated fry station—directly impacts customer satisfaction and your operational efficiency.

In this guide, we’ll take you through exactly how different warming solutions can enhance your kitchen operations, exploring practical insights, top brands, and proven techniques to maximise both quality and profitability.

For a closer look at professional-grade chip warming equipment that aligns perfectly with your business needs, visit our specialised collection at KW Commercial Kitchen.

Why Food Warmers Matter: It’s About More Than Just Heat

Many restaurant owners underestimate just how much serving temperature affects customer satisfaction. Sure, quality ingredients and skilled cooking are crucial—but even perfectly fried chips become instantly forgettable when served lukewarm or soggy. Hot, crispy food doesn’t just taste better; it directly influences whether customers choose your business again.

Imagine this scenario: A customer orders chips from your café on a busy lunch break, but instead of receiving golden, crunchy chips, they’re handed something soft and lifeless. Disappointed, they don’t return—and they’re likely telling others about their poor experience. Each lost customer might represent just a $15 lunch today, but considering repeat visits, referrals, and negative reviews online, the actual cost quickly escalates. Industry research indicates losing just one regular customer can cost Australian food businesses anywhere from $30 to $50—or even more, considering lifetime customer value.

Now, multiply that single loss across several customers each week, and the impact on profitability is substantial. Quick-service giants like McDonald’s and KFC understand this reality deeply. Their kitchen operations heavily rely on carefully chosen warming equipment—not just to keep chips and nuggets hot, but to maintain consistency and speed. Warmers ensure peak-hour orders flow without delay, keeping long lines satisfied and service times minimal.

This principle also holds true beyond fast food. Busy food courts depend on heated displays to keep foods appealing and ready for quick turnover, preventing customer frustration. Similarly, school canteens and libraries offering simple snacks use compact warmers to manage rushes efficiently, maintaining quality even when serving hundreds of hungry students in short lunch breaks.

In short, investing in effective warming solutions isn’t just about temperature; it’s about ensuring customers leave satisfied and eager to return. Every hot, delicious chip you serve is another step toward building loyalty and enhancing your business reputation.

Understanding Your Options: Chip Warmers, Dumps, Scuttles & Heated Displays Explained

Choosing the right warming solution starts with clearly understanding each type of equipment and how it supports your business goals. Let’s simplify this by breaking down the four most common categories used across Australian foodservice businesses.

Chip Warmers: Reliable General Holding

Commercial chip warmers are designed primarily to maintain the temperature and crispiness of fried foods after cooking. Typically enclosed and temperature-controlled, these units prevent food from drying out or becoming soggy, making them perfect for cafes, smaller takeaways, or snack bars needing steady yet moderate output.

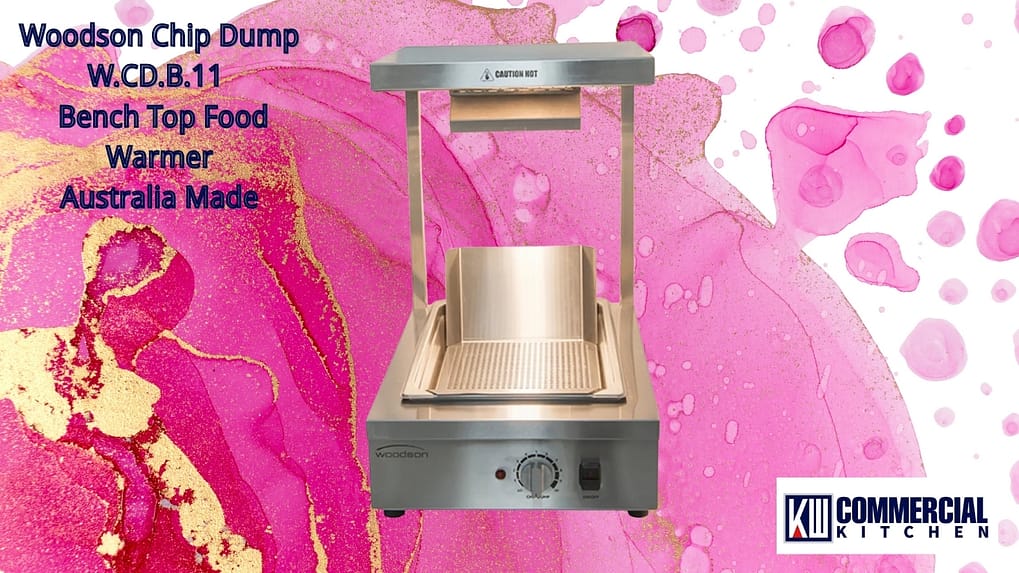

Chip Dumps and Scuttles: Built for High-Volume Service

Chip dumps (also known as chip scuttles) cater specifically to high-demand kitchens such as busy fish and chip shops or fast-food outlets. Their key advantage is open, ventilated construction—often featuring perforated trays or drainage areas—allowing excess oil and steam to escape. This design preserves crispiness even during peak service periods. If your operation closely resembles a high-turnover environment like a popular local takeaway, investing in a robust chip dump is essential.

Heated Displays: Attract and Serve with Style

Heated display cabinets offer both visual appeal and practical warming. Popular in food courts, bakeries, cinemas, and cafés, these units keep products visible, hot, and ready for immediate service. Their transparent, illuminated displays encourage impulse purchases while maintaining optimal food quality. If your business involves grab-and-go offerings—such as pastries, pies, or hot snacks—a heated display will boost both customer experience and sales.

Fry Stations: Integrated Solutions for Maximum Efficiency

Fry stations (or chip stations) integrate cooking and warming processes into one efficient workflow. Commonly found in high-capacity kitchens like McDonald’s or KFC, these stations streamline service by reducing the time between frying and serving. Staff can efficiently handle high-volume orders without compromising food quality or speed, making these units ideal for fast-food restaurants or busy school canteens managing tight lunch schedules.

Knowing precisely which warmer suits your specific needs not only improves operational efficiency but also significantly enhances customer satisfaction. Clearly defining your requirements—from volume to customer flow—ensures you choose equipment that maximises quality and profit.

Selecting Your Chip Warmer: Size, Power, Configuration, and Material Considerations

Choosing the best chip warmer isn’t just about keeping food hot—it’s about strategically matching the equipment to your kitchen’s needs and workflow. Let’s examine the four crucial factors: size, power efficiency, configuration, and materials.

Matching Size to Your Operational Needs

First, consider your busiest hours. If you regularly experience lunch or dinner rushes, opt for a larger-capacity freestanding warmer or chip dump that comfortably handles high-volume batches. Freestanding units offer robust capacity and quick access, ideal for busy fish and chip shops, food courts, or fast-food outlets. Conversely, if space is limited or your operation is smaller-scale, a compact benchtop warmer provides excellent performance without cluttering your workspace—perfect for cafés, small takeaways, or school libraries serving snacks.

Understanding Power and Energy Efficiency

Energy efficiency directly affects your operational costs. Australian food establishments typically use 10A or 15A electrical circuits for warmers. Choosing equipment that combines efficient heating elements and smart thermostatic controls ensures consistent temperatures while reducing unnecessary energy use. During quieter hours, units with adjustable settings allow you to maintain food quality without consuming excess electricity, significantly cutting your energy bills.

Configuration: Streamlining Workflow with Passthrough Design

For high-traffic environments—especially drive-through restaurants or bustling food courts—passthrough warmers dramatically enhance efficiency. Staff can load fresh chips or fried foods on one side, while service staff effortlessly access them from the opposite side, speeding up orders and maintaining smooth customer flow. Quick-service restaurants like McDonald’s and KFC rely heavily on passthrough fry stations to keep pace with intense customer demand, demonstrating this design’s proven operational benefit.

The Importance of Stainless Steel

Material quality is non-negotiable in professional kitchens. Stainless steel warmers aren’t just recommended—they’re often required by Australian food safety standards. This material is exceptionally hygienic, resisting rust, bacteria, and contamination. It’s also incredibly durable and easy to clean, ensuring equipment longevity even under heavy daily use. Investing in stainless steel chip warmers and heated displays not only meets regulatory compliance but ensures consistent food quality, customer safety, and equipment reliability.

By carefully evaluating these key factors—size, power efficiency, workflow configuration, and material quality—you’ll select warming solutions perfectly aligned with your kitchen’s unique needs, boosting both operational efficiency and customer satisfaction.

Brand Spotlight: Comparing Top Commercial Chip Warmer Brands

Choosing the right brand is critical when selecting commercial warming equipment. Each brand offers distinct strengths suited to varying business needs. Below is an objective comparison to help simplify your decision:

| Brand | Market Positioning | Key Strengths | Ideal Use Cases |

|---|---|---|---|

| Anvil | Reliable, Cost-effective | Durability, straightforward design, excellent value for money. | Cafés, small restaurants, budget-conscious kitchens seeking dependable performance. |

| Benchstar | Compact and Efficient | Space-saving design, efficient heating elements, easy maintenance. | Limited-space venues, cafés, school libraries, snack bars. |

| Woodson | Established Australian Favourite | Robust build quality, reliable after-sales support, trusted by many Australian kitchens. | Restaurants, takeaways, schools, and commercial kitchens across Australia. |

| Culinaire | Premium, High-End Performance | Superior design, precise temperature control, excellent durability and aesthetics. | Fine dining restaurants, upscale food courts, high-end catering services. |

| Frymax | High-Volume Specialist | Designed specifically for heavy-duty, high-volume operations; fast and consistent heating. | Fast-food chains, busy fish and chip shops, stadiums, school canteens. |

| Hatco | Global Leader, Advanced Tech | Cutting-edge heating technologies, excellent build quality, extensive global reputation. | International chains, cinemas, large-scale catering events, high-demand food courts. |

Ultimately, selecting the right brand should align closely with your operational demands, kitchen size, customer flow, and budget constraints. Whether your priority is durability, space efficiency, premium performance, or high-volume reliability, understanding each brand’s unique strengths helps ensure your investment delivers optimal returns.

Keep Fried Foods Warm and Ready to Serve

The KW Commercial Kitchen Difference: Honest Advice, Genuine Expertise

At KW Commercial Kitchen, we understand that choosing commercial kitchen equipment isn’t always straightforward—there are countless brands, sizes, and features to consider. Admittedly, we’re not perfect; no one in this fast-moving industry can claim to be. However, we’re deeply committed to providing genuine, honest advice drawn from our extensive experience working with diverse Australian food businesses.

What sets us apart is our dedication to truly understanding each customer’s unique situation. We don’t just recommend equipment—we help you match the right warming solution specifically to your operational needs, kitchen size, and budget constraints. This customised guidance comes from countless conversations with restaurant owners, chefs, school canteen managers, and café operators who’ve shared their real-world challenges and experiences with us.

Recently, we assisted a popular family-owned fish-and-chip shop facing customer dissatisfaction due to inconsistent chip quality during busy Friday nights. After careful consultation, we suggested a durable and efficient passthrough chip warmer from our range. This simple yet effective solution significantly improved their service speed and food quality, reducing customer complaints noticeably within weeks. Though we faced initial delays in delivery—something we’re actively working to minimise—our transparent communication and commitment to resolving issues earned trust and strengthened our partnership.

We’re continuously refining our processes, staying current with industry standards, and carefully selecting products for our catalogue. Our range of commercial chip warmers—available at our online store—is thoughtfully curated, balancing affordability, reliability, and performance.

At KW Commercial Kitchen, our promise isn’t perfection; rather, it’s integrity, practical support, and genuine effort. We’re here to ensure your kitchen equipment choices are informed, beneficial, and profitable. Because at the end of the day, your success is ours too, and that’s why we work tirelessly to earn your trust—one honest recommendation at a time.

The Science of Keeping Food Perfectly Warm: Temperature, Texture & Timing

Serving delicious, hot food consistently isn’t just about having good equipment; it’s about understanding how temperature and timing impact the texture and quality of each menu item. Even the best warmer can’t perform at its peak without correct settings and careful management.

Optimal Holding Temperatures and Times

- Chips and Fries: Ideal holding temperatures range between 60-70°C. This temperature ensures fries remain crispy by balancing heat retention and moisture control. Generally, fries maintain peak texture for approximately 15-20 minutes before quality declines noticeably.

- Chicken Nuggets: Keep nuggets at around 65-75°C, but bear in mind that crispiness fades quickly after about 20 minutes. Beyond this timeframe, texture can degrade significantly, becoming overly chewy or soft.

- Fried Fish: Fish fillets and similar fried seafood items are delicate and hold best at slightly lower temperatures of 60-65°C. Quality typically remains optimal for a maximum of 15 minutes. Exceeding this timeframe risks the fish becoming dry or the batter soggy.

How Warmer Design Impacts Food Quality

The design of warming equipment significantly influences food texture and freshness. Different heating methods—such as overhead heat lamps, base heaters, or even humidity-controlled cabinets—each have unique effects:

- Overhead Heaters (Heat Lamps): Primarily use radiant heat, ideal for short-term holding. They’re excellent for maintaining crispiness but can dry out foods if held too long without humidity control.

- Base Heaters: Heat from below helps maintain consistent internal temperature and texture. Perforated bases in chip dumps, for instance, help drain excess oil, keeping fries crispy longer.

- Humidity-Controlled Warmers: Adding controlled moisture can prevent delicate foods like fried fish or chicken from drying out. However, excessive humidity risks making crispy items soggy, so precise temperature and humidity balance is crucial.

Understanding these nuances allows kitchen staff to manage holding conditions better, ensuring food served to customers is consistently appealing. Effective food warming isn’t merely about setting a temperature dial; it’s about intelligently using your equipment to meet your kitchen’s unique demands, ensuring every customer receives the quality they expect.

Choosing the Right Warmer for Your Business Type

Every kitchen has unique demands, influenced by factors like customer flow, menu complexity, and even regional climate. Selecting the appropriate warming solution can substantially enhance operational efficiency and customer experience. Let’s explore tailored recommendations for different business types commonly found across Australia.

Quick-Service Restaurants and Drive-Throughs

High-volume kitchens like McDonald’s or KFC face intense demand, especially during peak hours. Passthrough warming units are ideal here, designed specifically for rapid service and efficient workflow. These warmers allow kitchen staff to load freshly cooked food from one side, while service teams quickly access orders from the opposite side. By minimizing wait times, these passthrough solutions keep service fast, reducing bottlenecks and enhancing customer satisfaction.

Restaurants and Cafés

Restaurants and cafés typically need warming solutions that balance practicality and aesthetics. Heated display cabinets provide the perfect solution—allowing appealing presentation of freshly cooked pastries, pies, or savoury snacks. Moderate volume establishments benefit from compact yet visually attractive displays that entice customers, support impulse buys, and enhance the overall dining experience without overwhelming limited counter space.

Food Courts and Cinemas

For busy public venues like food courts and cinemas, durability and visual appeal are equally important. High-quality, robust heated displays with excellent visibility ensure that food remains appetizing even during quieter periods, maintaining a fresh appearance that attracts customers. Such displays typically feature reinforced construction to withstand heavy use and ensure consistent product quality throughout prolonged operational hours.

Schools, Hospitals, and Institutional Kitchens

Institutional settings such as school canteens and hospitals require equipment suited to batch cooking and holding. Warmers specifically designed for efficient bulk holding ensure large quantities of food remain at safe temperatures during extended serving periods. Reliability, ease of use, and simple maintenance are key, ensuring that foodservice staff can effectively manage service while prioritising food safety and quality.

Considering Australian Climate Conditions

Australia’s diverse climates also influence equipment choices. In regions like Queensland or the Northern Territory, humidity and heat present unique challenges. Warmers with adjustable humidity control help mitigate these conditions, preserving the crispiness of fried foods and preventing moisture-related quality issues. Conversely, establishments in colder climates, such as Victoria or Tasmania, may focus more on consistent internal heat retention to keep food appealingly hot during colder seasons.

Matching your warmer to your specific business type and regional environment ensures your investment directly supports operational efficiency, food quality, and ultimately, customer satisfaction and loyalty.

Smart Installation & Effective Placement: Maximising Your Warmer’s Performance

Choosing the perfect chip warmer is only half the solution—installation and placement are equally crucial to ensuring maximum efficiency and safety. Proper positioning not only boosts operational workflow but also ensures food quality and kitchen safety.

Strategic Placement Near Fryers

The ideal location for chip warmers, especially in busy takeaways or quick-service environments, is directly adjacent to your fryers. Immediate proximity allows fresh chips to transfer seamlessly from fryer to warmer, significantly minimising heat loss and preserving crispiness. This simple yet strategic placement enhances both speed and food quality, vital during peak service hours.

Workflow and Ergonomic Considerations

Ergonomics and workflow efficiency are key to reducing staff fatigue and boosting productivity. Position warmers at a comfortable working height to minimise unnecessary bending or reaching. Consider traffic flow carefully—ensure equipment placement allows smooth movement between cooking, warming, and service areas. For passthrough warmers, easy access from both kitchen and service sides greatly improves order turnaround times, particularly beneficial in high-volume establishments like drive-throughs or food courts.

Essential Installation and Safety Tips

- Ensure adequate ventilation around warming equipment to prevent overheating and ensure compliance with Australian kitchen safety standards.

- Verify electrical compatibility (typically 10A or 15A circuits) and ensure installations are performed by qualified electricians to maintain safety and warranty validity.

- Always follow manufacturer’s guidelines for clearance distances, especially when placing warmers near combustible materials.

Staff Training for Best Results

Proper staff training is indispensable. Ensure your team thoroughly understands the equipment’s temperature settings, optimal holding times, and cleaning procedures. Regular training helps maintain food quality consistency and prolongs equipment lifespan, significantly reducing maintenance issues or operational downtime.

By thoughtfully managing installation, placement, and staff training, you ensure your warmer doesn’t merely keep food hot—it actively enhances your kitchen’s efficiency, safety, and customer satisfaction.

Keep Chips & Fries Hot

Keeping Your Warmer Running Smoothly: Cleaning, Maintenance, and Efficiency Tips

Proper cleaning and routine maintenance aren’t just chores—they’re essential practices that directly impact the lifespan, efficiency, and reliability of your chip warmer. By adopting a consistent schedule and some straightforward energy-saving strategies, you’ll significantly extend equipment life and reduce operational costs.

Daily and Weekly Cleaning Schedules

- Daily: At the end of every service day, thoroughly remove food residues and crumbs from warming trays and drainage areas. Use a soft cloth and mild detergent to clean stainless steel surfaces gently. Dry thoroughly to prevent water spots or corrosion.

- Weekly: Deep clean removable trays, perforated bases, and glass panels. Check heating elements for grease buildup and clean gently with manufacturer-approved products to maintain optimal heating efficiency.

Routine Maintenance Checklist

- Inspect heating elements weekly for consistent heat distribution.

- Regularly check electrical cords and connections for wear, damage, or fraying to maintain safety and reliability.

- Monthly, ensure thermostats and temperature sensors are functioning correctly, maintaining accurate temperatures for food safety and quality.

- Annually schedule a professional service inspection to address potential issues early, reducing downtime and extending equipment lifespan.

Energy-Saving Techniques

- Adjust temperature settings according to service volume—use lower holding temperatures during slower periods to conserve energy without compromising food quality.

- Switch off equipment during prolonged quiet times or schedule standby modes if available, significantly reducing electricity bills.

- Preheat warmers just before service peaks rather than running them continuously, efficiently managing energy use.

Managing Warmers During Busy vs Quiet Periods

During peak periods, maintain warmer temperatures and ensure quick food rotation to sustain food quality. Train staff to closely monitor food holding times, removing older batches first (FIFO method).

Conversely, during quiet periods, reduce warmer temperatures slightly while ensuring food remains above safe holding standards. Consider batch-cooking smaller portions during these times to minimise waste, energy use, and maintain product freshness.

Following these practical steps ensures your chip warmer consistently delivers top performance, maximises food quality, and helps maintain a profitable, efficient kitchen.

Real-World Success: How the Right Warmer Makes a Difference

Real improvements come from practical changes. Here are two honest and illustrative examples of Australian food businesses successfully using commercial warming solutions to significantly enhance their operations:

Case Study 1: Small Café Boosts Efficiency and Customer Satisfaction

A popular suburban café in Melbourne faced recurring problems during busy lunch hours: staff struggled to keep chips and snacks hot due to limited kitchen space and outdated warming equipment. Recognising the issue, the café owner replaced their older, bulky warmer with a modern, compact benchtop warmer. This small yet strategic shift freed up valuable workspace and dramatically improved operational flow.

Within weeks, the café noticed significant changes. Staff could serve customers much faster, with throughput increasing by roughly 25%. The chips remained consistently hot and crispy, prompting positive reviews and noticeably fewer customer complaints about food quality. Operationally, the new benchtop warmer reduced energy usage due to its efficient heating system, offering immediate savings on utility bills—a clear benefit for the café’s modest budget.

Case Study 2: Busy Fast Food Outlet Reduces Complaints by 40%

In a bustling coastal takeaway shop in New South Wales, peak summer months brought both high profits and high stress levels. Customers frequently complained about soggy or lukewarm chips due to delays between frying and serving. After a careful consultation, the owner decided to invest in a robust passthrough chip scuttle designed specifically for high-volume service.

The result was dramatic. Because kitchen staff could now efficiently transfer freshly cooked chips directly into the warmer, the chips remained crisp and hot, even during peak periods. Customer complaints dropped sharply—by approximately 40%—within the first month. The smoother workflow significantly reduced stress on employees, improving both staff morale and retention rates. The takeaway also reported increased repeat visits, attributing this directly to improved food quality and quicker service times.

These scenarios demonstrate clearly that thoughtful investment in appropriate warming equipment can lead to substantial improvements—not just in food quality, but in customer loyalty, operational efficiency, and overall business success.

Conclusion: Turning Warm Food into Customer Loyalty and Profit

Throughout this guide, we’ve explored why investing thoughtfully in commercial warming equipment is much more than a simple kitchen decision—it’s a strategic move directly tied to your business’s success. The right warmer doesn’t just keep your chips hot; it helps ensure consistently high food quality, supports faster service during peak times, and significantly reduces waste and operational costs during quieter periods.

Whether managing a fast-paced takeaway, a welcoming café, or a bustling food court, your choice of warmer can profoundly impact customer experience and satisfaction. As illustrated through real-world case studies, selecting equipment that aligns closely with your business’s specific needs dramatically enhances customer retention, reduces complaints, and directly contributes to profitability.

However, we also understand that navigating all the options available can feel overwhelming. That’s why expert advice tailored specifically to your unique operational needs is invaluable. At KW Commercial Kitchen, we’re committed not only to offering high-quality equipment but also honest, practical guidance to help you make informed choices that genuinely benefit your business.

If you’re considering upgrading your warming equipment or simply seeking professional insights, don’t hesitate to reach out. Our dedicated team is here to help ensure your equipment investment translates into real operational improvements, satisfied customers, and sustainable profits.

Choosing wisely today means greater success tomorrow—turning the simple warmth of perfectly held food into lasting customer loyalty and tangible business growth.

Frequently Asked Questions (FAQs)

What temperature should I set my chip warmer at?

The ideal holding temperature for chips is typically between 60-70°C. Maintaining this range helps keep chips crispy and fresh-tasting without drying them out.

How long can I keep fries in a warmer before they lose quality?

Fries maintain optimal crispiness and flavour for approximately 15-20 minutes. Beyond this time, quality begins to decline, affecting taste and texture.

Are commercial chip warmers expensive to run?

Generally, chip warmers are energy-efficient, especially newer models with advanced thermostatic controls. Operating costs typically remain manageable—around a few dollars per day—depending on unit size, power rating, and usage duration. Choosing energy-efficient models and smart operational practices (like reducing heat settings during slow periods) can significantly lower costs.

What’s the difference between a chip dump and a heated display?

A chip dump is designed specifically for holding fried foods such as chips, featuring open designs with perforated trays to maintain crispiness. A heated display is enclosed and used primarily to keep various foods visibly appealing and warm, ideal for pastries, pies, and other ready-to-serve items.

How often should I perform maintenance on my chip warmer?

Routine cleaning is recommended daily, while a deeper clean and maintenance check—such as inspecting heating elements and electrical connections—should occur weekly. Professional servicing is advised annually to ensure optimal performance and longevity.

Can I use my food warmer for different types of foods besides chips?

Yes, many commercial warmers are versatile, suitable for various items including fried chicken, fish, onion rings, and other finger foods. However, always verify the unit’s suitability regarding moisture control and temperature requirements for specific menu items.

Which brands are considered most reliable for chip warmers in Australia?

Brands like Woodson, Anvil, Hatco, Culinaire, Benchstar, and Frymax are highly regarded in Australia for durability and reliability. Each has unique strengths, so choose based on your specific operational needs and budget.

Do commercial food warmers require special electrical installations?

Most commercial food warmers in Australia typically run on standard 10A or 15A electrical circuits. Always check specific unit requirements before installation, and consult a licensed electrician to ensure safe and compliant connections.