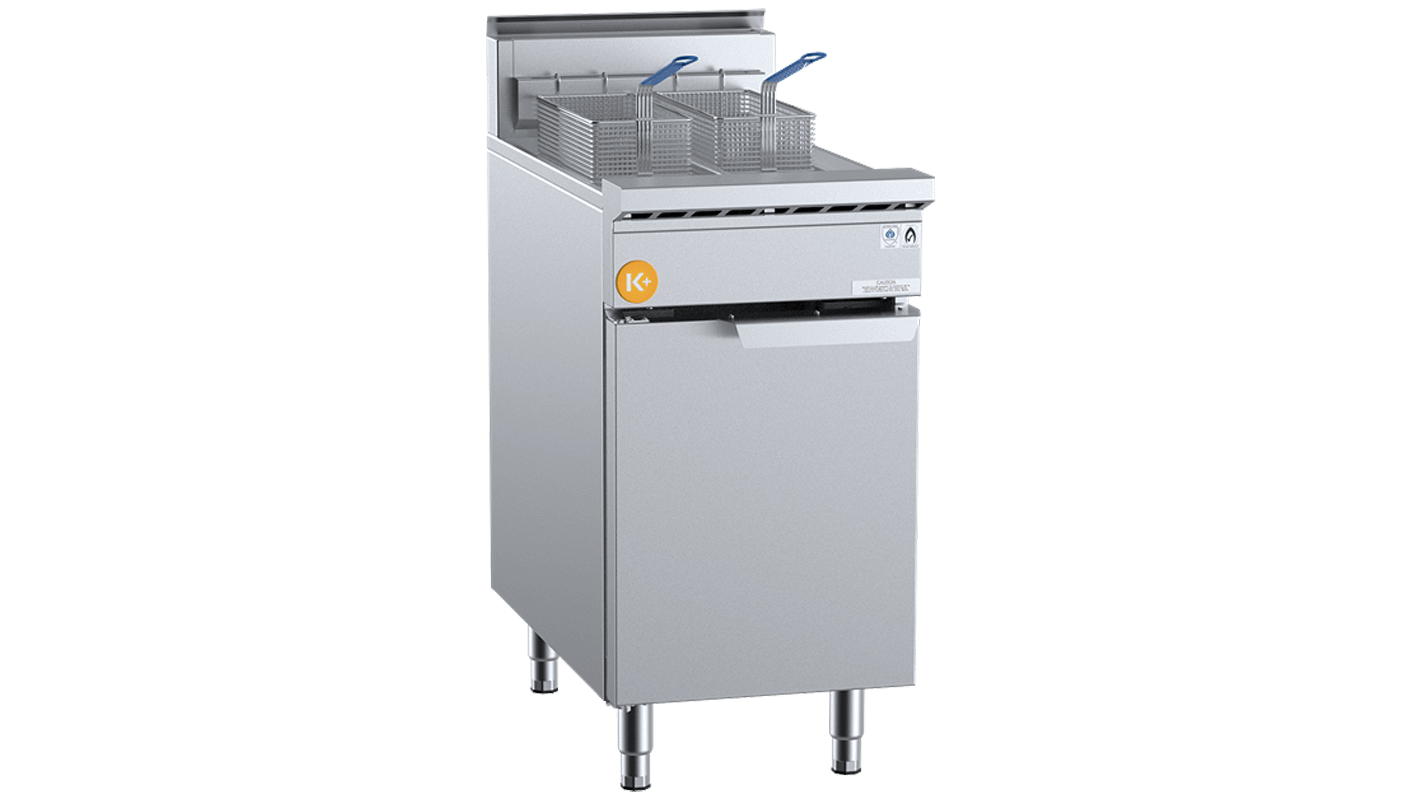

B+S K+ KTF-451S Split Tank Turbo Fryer – 450mm Gas

Updated:

At KW Commercial Kitchen, the B+S K+ KTF-451S split tank turbo fryer delivers

2 × 13.5L oil capacity, a powerful 76MJ/h multi-jet target burner and a compact

450mm footprint. With stainless steel construction, centre cool zone pans and built-in flame failure

protection, it is a commercial-grade solution for Australian restaurants, cafés and quick-service kitchens

needing fast, consistent deep frying.

Expert’s note

“For busy professional kitchens, the B+S K+ KTF-451S stands out because its split 13.5L pans and

efficient target burner let you run different products side by side while keeping oil quality stable through the

centre cool zone.”

Built for Australian high-output frying lines

The B+S K+ KTF-451S is a heavy-duty split pan turbo fryer engineered for continuous commercial use. AISI

grade stainless steel construction, cool zone split pans and an efficient multi-jet target burner combine to deliver

fast recovery times, reduced oil degradation and reliable service in demanding commercial kitchen and

professional kitchen environments.

Key features & specifications

- Capacity / Output: 2 × 13.5L oil capacity split pans (27L total)

- Temperature / Range: Thermostatically controlled oil temperature with over-temperature cut-out

- Power / Fuel: 76MJ/h gas input (Natural Gas or LP Gas) turbo multi-jet target burner

- Dimensions (W×D×H): 450 × 840 × 1030mm

- Weight: 90kg

- Construction: AISI grade stainless steel frame with 1.5mm thick stainless steel split pan, centre cool

zone, inclined base and heavy duty lockable oil drain valve - Safety: Flame failure device, over-temperature safety cut-out and manual ignition to pilot the burner

- Accessories: Supplied with baskets, fish plate and night covers

- Warranty: 18-month commercial warranty (conditions apply)

Compliance & safety (AU)

- Gas: 76MJ/h NG or LPG. 3/4″ BSP gas inlet, 1″ BSP oil outlet. Supply pressure 1.0kPa (NG) or

2.6kPa (LPG). Install and commission by a licensed gas fitter in accordance with AS/NZS 5601.1 and local

regulations. - Location: Indoor commercial kitchens only with suitable extraction canopy and make-up air.

- Approval: Certified gas appliance (approval number GMK 10683 – refer to current manufacturer

documentation).

Convenience & usage advice

- Split pan flexibility: Use one 13.5L pan for high-crumb foods and the other for chips or low-crumb items

to keep oil fresher for longer and reduce flavour transfer. - Cool zone design: The centre cool zone helps crumbs settle away from the cooking area, extending oil

life and improving product consistency. - Easy draining: The heavy duty lockable oil drain valve and inclined base simplify oil changes and

waste removal at the end of service. - Service friendly: Front access to the combination control valve and components makes routine servicing

faster and less disruptive.

Ideal applications

- Busy restaurants and hotel kitchens needing a compact, commercial grade gas fryer line

- Cafés, bars and bistros producing chips, calamari, schnitzels and fried sides throughout the day

- Quick-service and takeaway operations that require split pans for allergen separation or menu flexibility

Please note: product image is for reference only. Final supplied model and accessories may vary slightly from the image shown.

Is this unit right for you?

- Best for: Restaurants, cafés, hotel and club kitchens needing a compact 450mm gas fryer with split pans

for flexible production and better oil management. - Consider alternatives if: You require higher total oil capacity, a battery of multiple fryers, or

have extremely limited extraction or gas supply. In those cases, consider larger multi-tank fryers or electric

models. - Explore the range: Compare similar models in our

commercial gas fryer category.

Smart Energy & Sustainability

★ Energy Snapshot (Gas)

- Rated Input: 76MJ/h gas (NG or LPG) turbo burner

- Typical Daily Use: 6–8 hours per day in a busy commercial kitchen

- Approx. Daily Energy: 456–608MJ/day (≈ 127–169kWh equivalent of heat output)

- Estimated Running Cost: Approximately AUD $18–$24/day, assuming $0.03–$0.04 per MJ and moderate

duty cycle. Actual cost will vary with gas tariff, load and operating hours.

★ Efficiency Comparison

- Target burner design: Multi-jet turbo burner focuses heat directly into the pan for rapid

recovery compared with older atmospheric designs. - Cool zone oil management: Centre cool zone reduces crumb burn-off and helps extend oil life

versus flat-bottom fryers. - Split pan flexibility: Run one pan during off-peak periods to save gas and reduce oil volume in

use.

★ Sustainability Highlights

- Optimised burner and cool zone design help reduce oil wastage and frequency of complete oil changes.

- Durable stainless steel construction is designed for long service life in commercial environments, reducing

replacement cycles. - Suitable for connection to high-efficiency kitchen hoods to improve overall heat and fume capture.

★ Eco Badges

♻ Extended oil life 🔋 High-output gas burner 🌏 Commercial kitchen efficiency 🔧 Service-friendly design

★ Performance Bars

Energy Efficiency: ███████░░ 7/10 Performance: █████████░ 9/10 Eco Performance: ███████░░ 7/10

CO₂ Equivalent: At around 456–608MJ/day, annual usage at full load is

roughly comparable to driving a medium petrol car about 35,000–45,000km per year. Reducing idle time and using only one

pan during quiet periods can significantly cut gas use and emissions.

Smart Recommendation: Choose the KTF-451S if you need a compact, powerful

split tank fryer that balances high output with better oil management and sensible gas use in a commercial kitchen.

At a glance

- 450mm wide split tank gas turbo fryer with 2 × 13.5L pans

- 76MJ/h multi-jet target burner with flame failure and over-temperature protection

- AISI stainless steel construction with cool zone and lockable oil drain

- Supplied with baskets, fish plate and night covers, backed by 18-month warranty

Frequently Asked Questions

1) How do I clean the fryer daily without damaging it?

Allow the oil to cool to a safe temperature, then drain using the lockable oil valve into a suitable container.

Wipe down the pans, baskets and fish plate with a food-safe degreaser and non-abrasive cloth or brush. Avoid

steel wool or harsh abrasives that could damage stainless steel. Rinse, dry thoroughly and ensure all components

are fully dry before refilling with oil.

2) How can I manage gas use and running costs efficiently?

Use only one split pan during quiet periods, keep the fryer at cooking temperature only when needed and avoid

unnecessary idling between batches. Regularly skim crumbs to reduce heat loss and oil breakdown, and ensure the

fryer is correctly adjusted and serviced so the burner operates efficiently.

3) What installation and compliance requirements apply in Australia?

The KTF-451S must be installed and commissioned by a licensed gas fitter in accordance with AS/NZS 5601.1 and any

local authority requirements. It should be located under a compliant commercial kitchen exhaust canopy with

adequate make-up air and clearances as per the manufacturer’s instructions.

4) Are spare parts and service support available?

Yes. B+S K+ fryers are widely used in Australian commercial kitchens, and common parts such as thermostats, gas

valves and baskets are readily available. Our team can assist with sourcing genuine parts and recommending

service agents when you provide the model and serial number.

5) Can I integrate this fryer into a line of other B+S K+ equipment?

Yes. At 450mm wide and 840mm deep, the KTF-451S is designed to align with other B+S K+ series cooking equipment for

a clean, modular cookline. This helps maximise space in professional kitchens and gives a uniform, commercial

finish to your cook suite.

Ready to order or need expert advice?

Call 1300 001 366 or

contact our team.

Browse more options in our

commercial gas fryer range. Fast Australia-wide shipping.