Semi-Automatic Gyoza Dumpling Maker Machine – 1,500 pcs/hr Capacity

At KW Commercial Kitchen, we supply the Semi-Automatic Gyoza Dumpling Maker — a versatile dumpling and gyoza production machine that combines consistent forming precision with a compact, user-friendly design. Producing up to 1,500 pieces per hour, it’s perfect for Japanese gyoza, Chinese dumplings, samosas, and empanadas.

Built for restaurants, takeaways & food manufacturers

This semi-automatic gyoza machine delivers professional results for both hand-crafted and high-volume kitchens. Operators can easily adjust the dough thickness, filling amount, and dumpling size — ensuring every product meets your exact recipe specifications.

Key features & specifications

- Production capacity: up to 1,500 pcs/hour

- Applications: gyoza, dumpling, samosa, pierogi, empanada

- Voltage: 110V / 220V, 50 Hz single phase

- Construction: stainless steel frame with food-grade contact surfaces

- Control type: semi-automatic manual feed with motorized forming rollers

- Operation: automatic wrapping and crimping after filling placement

- Output adjustment: customizable dough thickness and filling volume

- Production type: interchangeable molds for different dumpling shapes

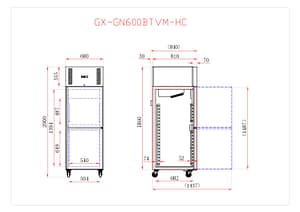

- Dimensions: compact countertop design for small kitchens

- Origin: Henan, China

Compliance & safety (AU)

- Electrical: 220V RCM-ready; installation by licensed electrician recommended.

- Food safety: FSANZ-aligned stainless construction and BPA-free food contact parts.

- Operation: manual supervision required; avoid overloading dough feed.

Convenience & usage advice

- Customisable setup: Machine can be tailored to your desired shape and size upon order.

- Easy cleaning: Removable molds and stainless surfaces simplify sanitation.

Ideal applications

- Japanese restaurants (gyoza)

- Chinese dim sum outlets

- Catering and frozen food production

- Samosa and empanada production lines

Frequently Asked Questions

1) How do I clean it daily without harming finishes?

Switch off and unplug the unit, disassemble the molds and trays, and wash with warm soapy water; avoid high-pressure washing or abrasives.

2) What routine maintenance keeps performance stable?

Lubricate mechanical joints monthly; inspect electrical connections and check forming rollers for wear.

3) What are the power and production requirements?

Operates on 110V or 220V 50Hz single phase; produces up to 1,500 pieces per hour depending on dough and filling.

4) What about installation and Australian compliance?

Connect via RCM-certified 220V plug; must comply with AS/NZS 3000 electrical safety and FSANZ food-contact standards.

5) Are spare parts and accessories available?

Yes – mould sets, filling nozzles, and rollers available on request or via OEM factory support.

Specs source: manufacturer data (Henan, China, 2024).

Ready to order or need expert advice?

Call 1300 001 366 or Contact our team.

Browse Dumpling Machines for more models.