Suzumo SSN-JLX Compact Sushi Machine – 4,800 pcs/hr Nigiri Maker

Updated:

At KW Commercial Kitchen, we supply the Suzumo SSN-JLX Compact Sushi Machine, the fastest and most precise nigiri sushi rice ball maker in its class. With a capacity of up to 4,800 pieces per hour and a unique comb-blade forming method, it creates perfectly fluffy, melt-in-mouth nigiri rice with consistent texture and shape.

Built for Australian sushi chefs & foodservice operators

The SSN-JLX combines high-speed production, integrated rice warming, and LCD touchscreen control for effortless operation. Adjust hardness, speed, and weight instantly, while maintaining rice grain integrity and traditional nigiri shape. Available with standard or large rice hopper options.

Key features & specifications

- Capacity: 3,000 / 3,600 / 4,200 / 4,800 pcs per hour (selectable)

- Weight per piece: 12 – 22 g (different mould unit for 12–16 g)

- Hardness setting: 7-step adjustment (Soft → Hard)

- Hopper capacity: 5.5 kg (standard) or 10 kg (large)

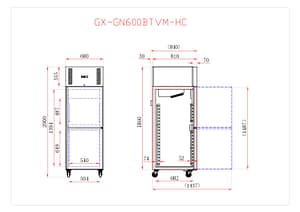

- Dimensions (W×D×H): 350 × 477 × 584 mm (standard hopper)

- Power input: AC 110–120 V, 60 Hz, single phase

- Power rating: 170 W

- Machine weight: approx. 25 kg

- Heat-retention: integrated rice warmer, adjustable temperature

- Optional: transfer unit, wasabi dispenser

Compliance & safety (AU)

- Electrical: RCM and CE compliant; single-phase plug connection.

- Food safety: FSANZ-aligned materials; hygienic design for rice handling and easy sanitisation.

- Certification: CE / UKCA certified for food production environments.

Convenience & usage advice

- Touchscreen control: Adjust speed, compression, and weight via high-definition LCD panel.

- Integrated rice warmer: Keeps rice at optimal temperature for soft, fluffy nigiri output.

Ideal applications

- Sushi restaurants & catering

- Japanese takeaways & bento production

- Food manufacturing & commissary kitchens

Frequently Asked Questions

1) How do I clean it daily without harming finishes?

Turn off power, disassemble forming unit, wash removable parts with mild detergent and warm water; dry completely before reassembly.

2) What routine maintenance keeps performance stable?

Clean rice hopper and mould daily; inspect sensors and comb blades weekly; keep heat-retention function calibrated for rice temperature consistency.

3) What are the power and space requirements?

Single-phase 110–120 V connection; compact footprint (350 × 477 mm) ideal for benchtop operation.

4) What about installation and Australian compliance?

Complies with CE / UKCA & RCM standards; install on level surface near dedicated power outlet; ensure hygienic workspace per FSANZ 3.2.2A.

5) Are spare parts and accessories available?

Yes – mould units, transfer conveyors, and rice hoppers available from Suzumo distributors worldwide.

Specs source: official Suzumo SSN-JLX / SSN-JLX-CE brochure (2023).

Ready to order or need expert advice?

Call 1300 001 366 or Contact our team.

Browse Sushi Machines for more Suzumo models.