Suzumo SVS-FCA Rice Sheet Making Machine – 1,250 Sheets/hr Compact Sushi Equipment

Updated:

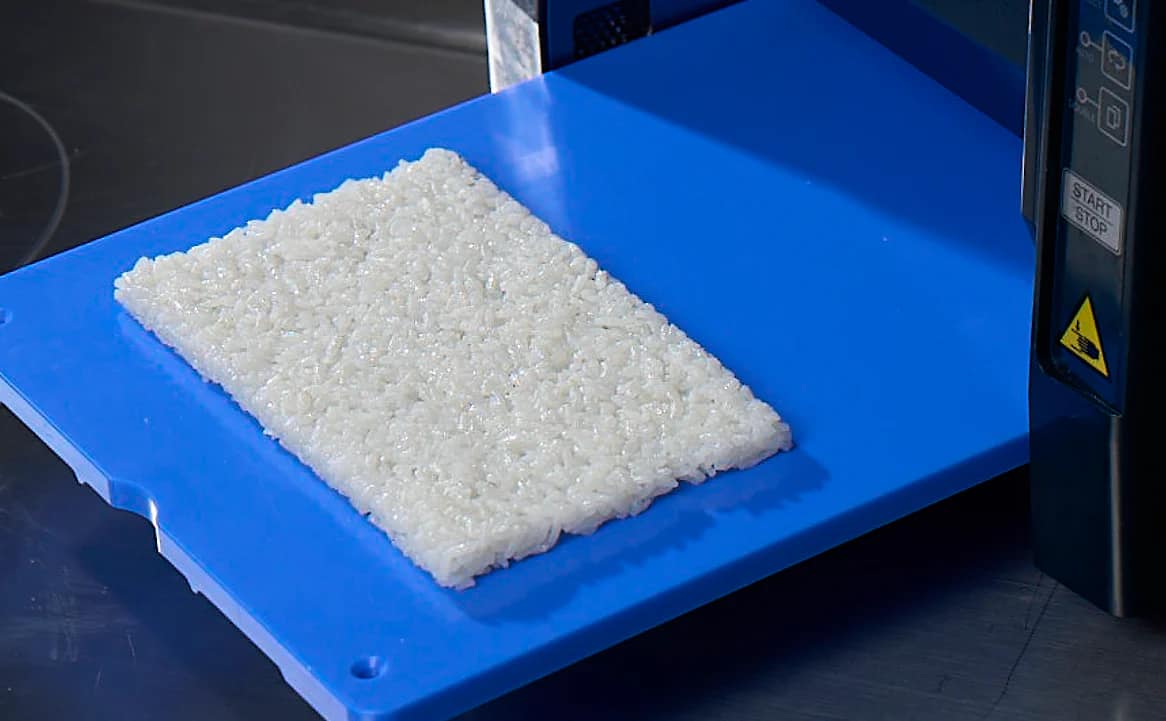

At KW Commercial Kitchen, we supply the Suzumo SVS-FCA – the next generation rice sheet making machine built for precision, speed, and ease of operation. Capable of producing up to 1,250 sushi rice sheets per hour, this high-performance unit automates rice sheet preparation for sushi rolls with consistent texture and thickness:contentReference[oaicite:0]{index=0}.

Built for Australian sushi chefs & catering production lines

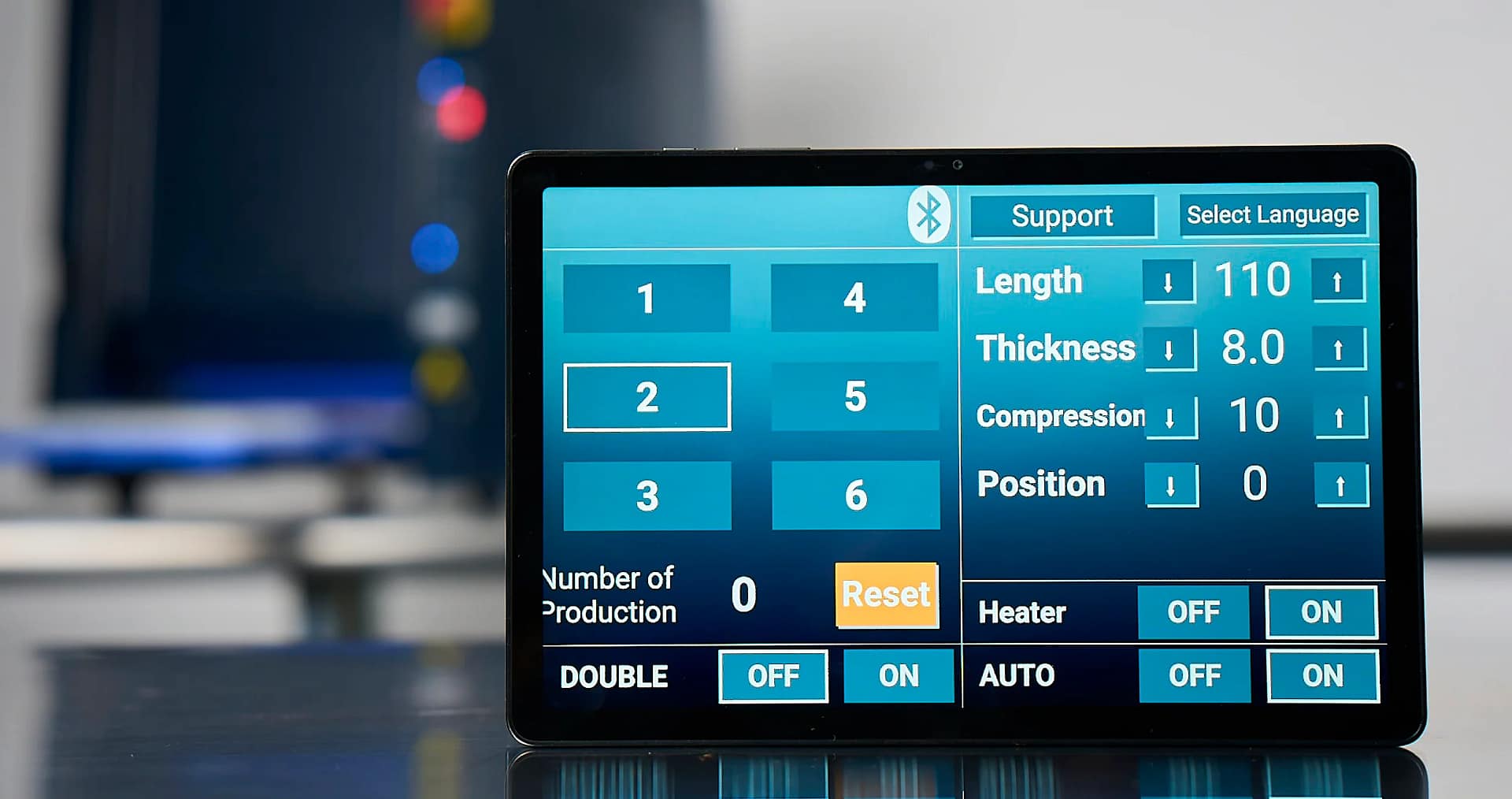

The SVS-FCA combines Suzumo’s proprietary rice pressing technology with automatic supply and double sheet modes to maintain uniform quality and efficiency. Its integrated control panel and optional mobile app make operation, cleaning, and maintenance simple for professional environments.

Key features & specifications

- Capacity: 1,250 sheets/hr (small roll, 7 mm thickness); 1,000 sheets/hr (medium roll); 750 sheets/hr (large roll)

- Rice amount per sheet: 70 – 300 g

- Hopper capacity: 10 kg cooked rice

- Dimensions (W×D×H): 350 × 468 × 570 mm (table closed) / 350 × 690 × 570 mm (max table)

- Power: AC 110–120 V / 50–60 Hz, 100 W

- Weight: 31 kg

- Functions: double sheet supply mode, automatic supply mode, 3 size memory

- Power cable: approx. 2 m

- Option: pick-up plate accessory

Compliance & safety (AU)

- Electrical: CE & RCM compliant single-phase connection.

- Food safety: FSANZ-aligned design using food-grade components; all parts (except hopper & lid) are dishwasher-safe.

- Certifications: NSF & UL listed for international foodservice compliance:contentReference[oaicite:1]{index=1}.

Convenience & usage advice

- Mobile control: Adjust roll size, thickness, and speed from the Suzumo smartphone app.

- Easy cleaning: Minimal detachable parts—dishwasher-safe for hygiene and quick turnaround.

Ideal applications

- Sushi restaurants & Japanese takeaways

- Commercial kitchens & production catering

- Grab-and-go or supermarket sushi production lines

Frequently Asked Questions

1) How do I clean it daily without harming finishes?

Remove the rice hopper and pressing components; wash parts in warm soapy water or dishwasher (excluding hopper & lid); dry completely before use.

2) What routine maintenance keeps performance stable?

Inspect the roller and feed sensors weekly; lubricate moving parts as instructed; recalibrate sheet thickness quarterly.

3) What are the power and space requirements?

Operates on standard 110–120 V outlet; compact footprint of 350 × 468 mm fits most prep benches.

4) What about installation and Australian compliance?

RCM & NSF certified; plug-and-play design; ensure operation on level surface and compliance with FSANZ hygiene requirements.

5) Are spare parts and accessories available?

Yes – pick-up plates, hoppers, and rice table components available through Suzumo Australia distributors.

Specs source: official Suzumo SVS-FCA brochure (2025):contentReference[oaicite:2]{index=2}.

Ready to order or need expert advice?

Call 1300 001 366 or Contact our team.

Browse Sushi Machines for more Suzumo models.