Maximise Kitchen Efficiency with Stainless Steel Corner Workstations

A stainless steel corner bench is a specially designed workstation built to fit neatly into the corner spaces of commercial kitchens. Highly popular in Australia’s busy cafés, restaurants, bakeries, and catering businesses, these benches optimise unused spaces, transforming them into functional and practical work areas. By integrating a corner workbench for kitchens into your commercial kitchen layout, you can significantly improve workflow efficiency and productivity.

Why do Australian businesses rely heavily on these commercial kitchen corner solutions? The answer lies in their exceptional space-saving design. Corner benches not only maximise kitchen storage capacity by efficiently utilising corner areas, but they also provide additional work surfaces without obstructing kitchen traffic flow. Constructed from premium stainless steel, they offer a hygienic, food-safe environment that’s easy to clean and maintain, ensuring compliance with strict Australian food safety standards.

Key Benefits of Stainless Steel Corner Benches:

- Space Saving: Efficiently utilises kitchen corner spaces, boosting overall kitchen productivity.

- Enhanced Kitchen Storage: Provides additional shelving and storage options beneath the work surface, ideal for kitchens with limited storage.

- Easy Maintenance: Stainless steel surfaces are highly resistant to stains and corrosion, making daily cleaning quick and simple.

- Food Hygiene and Safety: Meets Australian food hygiene regulations effortlessly by reducing contamination risks in your kitchen.

- Aesthetic Appeal: Sleek, modern stainless steel design improves the professional appearance and atmosphere of any commercial kitchen.

In this comprehensive guide, we’ll explore how implementing stainless steel corner benches in Australia can transform your kitchen’s efficiency, cleanliness, and profitability.

What is a Stainless Steel Corner Bench?

A stainless steel corner bench, often referred to as a kitchen corner workstation, is specifically designed to utilise corner spaces efficiently within commercial kitchens. Unlike a regular workbench or a sink bench, which typically occupy straight areas along kitchen walls, corner benches feature an angled design that perfectly fits into the intersection of two adjoining walls. This unique layout maximises every inch of available space, enhancing workflow and functionality in professional kitchens.

Key Stainless Steel Corner Bench Features:

- Angled Design: Uniquely shaped to fit neatly into kitchen corners, optimising space usage and providing a seamless connection between kitchen workstations.

- High-quality Stainless Steel: Durable, hygienic, corrosion-resistant, and easy to clean, making it ideal for heavy-duty commercial kitchen use.

- Optional Splashbacks: Available with or without splashbacks to protect walls from spills, enhancing cleanliness and maintaining hygiene standards.

- Additional Storage (Undershelf): Often includes an undershelf for convenient storage of kitchen utensils, pots, or ingredients, further maximising storage space.

Corner Bench vs Regular Bench – What’s the Difference?

Unlike regular benches or sink benches which have a linear design suitable for straight walls, corner benches are purpose-built to fit precisely into corner spaces, eliminating awkward gaps and underutilised areas. While standard benches serve specific tasks like food preparation or dishwashing, corner benches integrate seamlessly into your overall kitchen workflow, providing versatile usage such as prep areas, additional storage, or workspace extensions.

Common Sizes and Styles:

Commercial kitchens typically choose corner benches based on space availability and functional needs. Popular sizes in Australia include:

| Bench Size (mm) | Typical Use | Ideal Kitchen Types |

|---|---|---|

| 600×600 | Compact spaces, cafés, snack bars | Small kitchens, takeaway shops |

| 700×700 | Medium-sized prep stations, bakeries | Cafés, bakeries, small restaurants |

| 900×900 | Larger work areas, extensive storage | Restaurants, hotels, catering kitchens |

Understanding these differences and choosing the appropriate style and size ensures your stainless steel corner bench features perfectly align with your kitchen’s requirements, creating an efficient and productive workspace.

Why Invest in Stainless Steel Corner Benches?

Investing in a stainless steel corner bench can significantly transform your commercial kitchen’s functionality and profitability. Australian cafés, restaurants, bakeries, and catering facilities widely adopt these corner benches to address common operational challenges, such as limited space, inefficient workflow, and stringent hygiene regulations. Below, we outline the key benefits of stainless steel corner benches that demonstrate why they are a valuable investment for your commercial kitchen.

Maximise Your Kitchen Space

Commercial kitchens constantly battle with limited workspace, especially in bustling Australian city environments. Stainless steel corner benches cleverly utilise previously neglected corner areas, eliminating wasted space and ensuring no area is left unproductive. This strategic utilisation often increases usable workspace by up to 25%, greatly enhancing your kitchen’s overall efficiency.

Increase Productivity and Efficiency

By creating a seamless, integrated workspace, corner benches significantly improve workflow efficiency. Chefs and kitchen staff experience smoother, uninterrupted movement between preparation, cooking, and serving zones, reducing wasted steps and improving overall productivity. Studies in commercial kitchens have shown that efficient layouts featuring corner benches can boost staff productivity by up to 20%, directly contributing to your kitchen’s bottom line.

Ensure Compliance with FSANZ Standards

Hygiene is paramount in Australian food establishments, governed strictly by Food Standards Australia New Zealand (FSANZ). Stainless steel benches naturally comply with these standards due to their non-porous surface, ease of sanitisation, and resistance to corrosion. Investing in FSANZ compliant kitchen benches significantly reduces contamination risks and potential health violations, protecting your reputation and avoiding costly fines.

Enhance Kitchen Aesthetics and Professionalism

Stainless steel benches offer a clean, modern, and professional look. Integrating corner benches into your kitchen layout not only improves operational efficiency but also elevates your kitchen’s visual appeal. An attractive, organised workspace instils confidence among staff and positively impacts customer perceptions, enhancing your business’s overall image.

Key Benefits Summary:

| Benefit | Impact on Kitchen Operations | Statistic/Fact |

|---|---|---|

| Space Maximisation | Utilises corner areas effectively | Up to 25% more usable workspace |

| Increased Productivity | Smoother workflow and reduced staff movements | Boosts productivity by up to 20% |

| FSANZ Compliance | Reduces risk of hygiene violations and contamination | Compliant with Australian food safety regulations |

| Professional Appearance | Modern, hygienic, appealing environment | Enhances staff morale and customer trust |

Considering these factors, investing in stainless steel corner benches is more than an expense—it’s a strategic decision to enhance kitchen efficiency, hygiene compliance, and overall corner bench profitability for your business.

Who Should Use Stainless Steel Corner Benches?

When considering upgrading kitchen efficiency, understanding the ideal kitchen types for corner benches is essential. Stainless steel corner benches are specifically designed to benefit commercial kitchens of various sizes and purposes across Australia. Below, we clearly outline which businesses gain the most from implementing this practical solution:

Target Commercial Kitchen Corner Bench Users:

- Restaurants and Café Kitchens: Busy kitchens with constant food preparation greatly benefit from corner benches. They provide additional workspace for prepping ingredients, plating meals, and maintaining smooth kitchen workflows during peak hours.

- Bakeries: Stainless steel benches provide hygienic and spacious surfaces ideal for dough preparation, pastry assembly, and finishing touches, reducing contamination risks and ensuring compliance with Australian hygiene standards.

- Hotel Kitchens: Hotels with extensive catering services require efficient kitchen layouts. Corner benches streamline kitchen operations by maximising usable space, especially in compact or uniquely shaped kitchen areas.

- Food Production Facilities: Facilities involved in food manufacturing or processing rely heavily on stainless steel surfaces for hygiene, ease of cleaning, and durability. Corner benches help maximise operational efficiency, supporting high-volume production.

- Compact Kitchens: Small cafés, food trucks, and takeaway establishments facing space constraints find corner benches invaluable. They effectively utilise corner spaces, providing additional prep areas without crowding already limited floor spaces.

Food Types Best Suited for Stainless Steel Corner Benches:

Stainless steel is inherently hygienic and easy to clean, making corner benches ideal for preparing a wide range of foods, including:

- Fresh salads, sandwiches, and cold meals

- Pastries, dough-based products, and baked goods

- Meat and seafood preparation requiring high hygiene standards

- General food packaging and portioning tasks

By clearly identifying kitchen corner bench customers and their specific requirements, you can confidently choose stainless steel corner benches to optimise your kitchen space, maintain impeccable hygiene standards, and improve operational efficiency. Whether you’re running a bustling restaurant in Sydney, a boutique bakery in Melbourne, or a compact café in Brisbane, stainless steel corner benches offer versatile solutions tailored specifically to commercial kitchen needs across Australia.

How Corner Benches Increase Kitchen Profits?

Investing in stainless steel corner benches is one of the smartest kitchen profitability solutions for Australian hospitality businesses. Beyond their practical advantages, these benches deliver measurable financial benefits through increased productivity, improved hygiene standards, and enhanced customer and employee satisfaction.

Optimise Kitchen Space and Improve Productivity

Commercial kitchen efficiency directly impacts profitability. Using corner benches transforms unused spaces into productive work areas, streamlining workflow and allowing staff to perform tasks more smoothly. The strategic placement of corner benches reduces unnecessary movement within the kitchen, enabling staff to complete tasks faster and more efficiently. A recent hospitality industry survey found that kitchens using integrated corner benches improved staff productivity by approximately 15–20%, significantly reducing labour costs and improving turnaround times.

Enhance Hygiene and Avoid Costly Penalties

In Australia, adherence to strict food safety regulations is crucial. Poor hygiene can result in costly fines, temporary closures, and long-term reputation damage. Stainless steel corner benches, being corrosion-resistant and easy to sanitise, help maintain impeccable hygiene standards effortlessly, reducing contamination risks. By investing in corner benches, businesses minimise the likelihood of hygiene breaches and compliance issues—protecting both profitability and brand reputation.

Boost Employee Morale and Customer Experience

A well-organised and hygienic kitchen environment significantly boosts employee morale. Staff working in comfortable, functional spaces experience less stress, better teamwork, and higher job satisfaction, directly influencing productivity and service quality. In turn, customers receive higher-quality meals served efficiently, enhancing their overall dining experience and encouraging repeat visits, ultimately increasing business revenue.

Integration with Dishwashers and Sink Benches for Maximum Efficiency

Strategically placing corner benches adjacent to dishwashers and sink benches enhances cleaning efficiency and workflow. This arrangement creates an efficient cycle of prep, cooking, plating, serving, and cleaning. Corner benches provide additional workspace for sorting and pre-cleaning dishes before they reach the dishwasher, thus speeding up the cleaning process and improving overall kitchen throughput.

Real-World Example: Melbourne Café Boosts Profits

A popular café in Melbourne recently upgraded their kitchen layout by adding stainless steel corner benches strategically positioned next to their dishwasher and sink bench. Within six months, they reported:

- A 20% increase in staff productivity due to reduced movements and enhanced workflow efficiency.

- No food safety breaches or compliance issues reported during health inspections, a noticeable improvement compared to previous years.

- Customer feedback improved significantly, with many praising faster service times and improved meal presentation.

These practical examples illustrate clearly how stainless steel corner bench efficiency delivers tangible financial benefits. When correctly integrated into your kitchen, corner benches can significantly improve operational efficiency, hygiene compliance, employee satisfaction, and ultimately, profitability.

Types and Selection Guide of Stainless Steel Corner Benches

Choosing the right corner bench is essential for maximising your kitchen’s functionality and efficiency. Understanding the various types of stainless steel corner benches helps in making an informed decision tailored to your kitchen layout and operational needs. Below, we outline three popular designs offered by KW Commercial, each with unique advantages and recommended uses.

Right-Angled Corner Bench

A traditional, L-shaped bench designed precisely to fit into the kitchen corner, seamlessly connecting two perpendicular work areas. Ideal for kitchens needing straightforward layouts with optimal space utilisation.

- Pros: Maximises corner space, seamless workflow integration, easy to maintain hygiene.

- Cons: May limit workspace flexibility in smaller kitchens.

- Recommended Placement: Ideal for restaurant kitchens, cafés, or bakeries with clearly defined workstations.

Recommended Product: Kitchen Knock 600mm Right-Angled Corner Bench

Angled (Chamfered) Corner Bench

This bench features a cut-off corner design (chamfered edge), providing smoother kitchen navigation and easier access around sharp corners, improving kitchen traffic flow and accessibility.

- Pros: Enhanced accessibility, smoother workflow, reduces collision risks in busy kitchens.

- Cons: Slightly reduces storage space underneath.

- Recommended Placement: High-traffic commercial kitchens, catering facilities, and hotel kitchens with heavy staff movement.

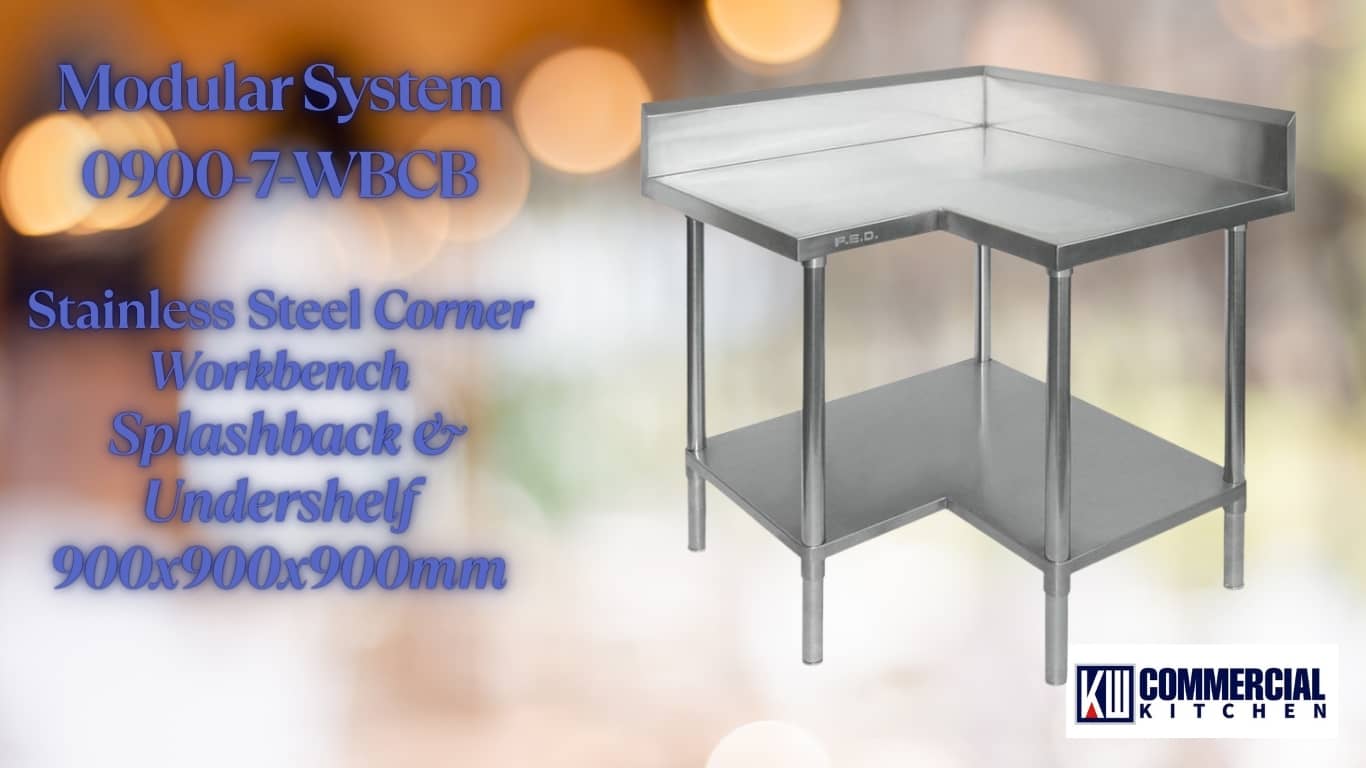

Recommended Product: FED WBCB6-0900 Angled Corner Workbench

Square Corner Bench

Featuring a symmetrical square shape, this bench provides generous workspace and additional storage beneath. Best suited for kitchens needing extra storage and extensive prep areas.

- Pros: Larger workspace, extra undershelf storage, versatile for multiple tasks.

- Cons: Requires more kitchen space compared to angled versions.

- Recommended Placement: Ideal for medium to large kitchens, such as restaurants, food production areas, and bakeries requiring significant prep surfaces.

Recommended Product: FED WBCB7-0700 Square Corner Workbench

Quick Comparison Guide

| Type | Best For | Main Advantage |

|---|---|---|

| Right-Angled Bench | Clearly defined kitchen layouts | Maximum corner utilisation |

| Angled (Chamfered) Bench | Busy kitchens with heavy foot traffic | Enhanced accessibility and movement |

| Square Bench | Large kitchen spaces needing storage | Extra workspace and storage capacity |

By following this concise corner bench buying guide, you can confidently select the best corner bench solutions tailored specifically for your kitchen’s needs, enhancing both operational efficiency and profitability.

Optimal Placement of Corner Bench and Kitchen Equipment

Strategically placing your stainless steel corner bench within your commercial kitchen is essential for achieving peak efficiency and workflow productivity. Effective kitchen equipment integration ensures smoother operations, reduces staff fatigue, and improves overall kitchen functionality. Here, we outline practical stainless steel corner bench layout tips to maximise your investment and streamline daily kitchen tasks.

Integrate with Dishwasher and Sink Bench

A highly recommended approach is positioning the corner bench adjacent to your dishwasher or sink bench. This integration creates an efficient workflow for dishwashing, cleaning, and food preparation. Staff can effortlessly move dishes from the preparation area on the corner bench directly to the sink or dishwasher, minimising handling time and improving cleanliness standards. Ideally, the corner bench should sit between prep areas and cleaning zones, allowing quick transitions between tasks.

Seamless Connection with Other Workbenches

Connecting the corner bench seamlessly with your existing kitchen benches or workstations is crucial for maintaining efficient workflow. This uninterrupted layout provides a smooth, continuous work surface, enabling staff to easily move prepared ingredients to cooking areas without disruption. Ensure the bench heights and depths match, and that any undershelf storage aligns neatly for additional organisation.

Proven Placement Strategies for Maximum Efficiency

- Create Task Zones: Group related equipment and benches together—preparation benches near storage areas, corner benches adjacent to sinks, and cooking equipment nearby, streamlining each operational step.

- Consider Traffic Flow: Position corner benches to reduce cross-traffic, ensuring staff can move freely without obstruction.

- Plan for Accessibility: Ensure frequently used utensils and ingredients are stored under or near corner benches for easy access, further enhancing productivity.

Successful Real-Life Example: Sydney Bistro

A busy Sydney bistro recently reconfigured their kitchen by integrating a stainless steel corner bench directly between their dishwasher and main preparation bench. Within months, the restaurant reported:

- A 25% reduction in time spent moving between workstations.

- Improved hygiene compliance due to smoother dishwashing and cleaning processes.

- Significant staff feedback indicating reduced fatigue and higher job satisfaction.

Quick Reference: Effective Placement Tips

| Placement Strategy | Benefit |

|---|---|

| Adjacent to dishwasher or sink bench | Streamlines cleaning process and reduces dish handling time |

| Seamlessly connect with existing benches | Creates uninterrupted workspace, boosts efficiency |

| Group related kitchen tasks and equipment | Minimises unnecessary movements, enhancing productivity |

By following these strategic corner bench placement strategies, Australian businesses can dramatically improve their kitchen’s operational efficiency, hygiene standards, and overall profitability.

Cleaning and Maintenance of Stainless Steel Corner Benches

Proper stainless steel bench maintenance is crucial for ensuring your corner bench stays hygienic, attractive, and functional long-term. Here, we provide a straightforward corner bench cleaning guide along with essential maintenance tips, helping you effortlessly preserve your investment and maintain Australian food safety compliance.

Simple and Effective Cleaning Schedule

- Daily (5–10 mins): After each shift, wipe down surfaces with warm water and mild detergent to remove crumbs, spills, and debris. Dry immediately to avoid water spots.

- Weekly (15–20 mins): Thoroughly clean benches using a gentle stainless steel cleaner. Polish surfaces with a soft, lint-free cloth following the grain direction to maintain shine and hygiene standards.

- Monthly (20–30 mins): Deep-clean undershelves and edges. Inspect corners and joints, removing any trapped dirt or residue. Consider using food-safe sanitiser monthly for enhanced hygiene.

Essential Corner Bench Care Tips

- Preventing Scratches: Always use chopping boards when preparing ingredients. Avoid using abrasive pads or harsh cleaners.

- Removing Water Spots: Quickly dry surfaces after cleaning with a dry microfiber cloth. For persistent spots, gently polish with diluted white vinegar solution.

- Regular Inspections: Monthly, inspect all screws, brackets, and connections to ensure stability and safety. Tighten any loose fittings immediately to maintain bench integrity.

Common Mistakes and How to Avoid Them

- Using Abrasive Cleaners: Avoid harsh chemicals or steel wool, as these damage the surface. Always choose mild detergents or stainless steel-specific cleaning products.

- Ignoring Immediate Spills: Quickly addressing acidic or oily spills prevents long-term stains or corrosion.

- Overloading Benches: Respect recommended weight limits to prevent bending or structural damage to the bench and undershelves.

By following these easy-to-implement corner bench care tips, your stainless steel corner bench will remain hygienic, attractive, and fully compliant with Australian health regulations, supporting your kitchen’s long-term operational success.

Important Considerations Before Buying Stainless Steel Corner Benches

When buying a stainless steel corner bench for your commercial kitchen, several critical factors should guide your decision to ensure maximum functionality, compliance, and return on investment. Here are essential considerations for selecting the ideal bench for your kitchen:

Bench Size and Space Compatibility

Accurately measure available corner spaces before purchasing. Consider how the bench integrates into your existing kitchen layout, ensuring enough room for staff movement and equipment placement. Choose bench dimensions that maximise available space without hindering kitchen traffic flow.

Budget and Cost-Effectiveness

Clearly define your budget beforehand, considering not only upfront costs but also durability, maintenance, and potential long-term savings. Investing slightly more upfront in higher-quality stainless steel benches often results in lower lifetime maintenance costs, better hygiene compliance, and enhanced productivity.

Compliance with FSANZ and Quality Standards

Ensuring your chosen bench complies fully with Australia’s strict food safety standards is mandatory. All stainless steel benches used in commercial kitchens must adhere to FSANZ kitchen requirements, including material grade (304-grade stainless steel is recommended), thickness (typically 1.2mm minimum), and hygienic construction. Non-compliant benches can lead to costly fines, penalties, and reputational damage.

Quick Checklist Before Purchasing:

- Verify accurate measurements and kitchen compatibility.

- Ensure compliance with Australian hygiene standards (corner bench compliance standards).

- Check stainless steel grade (304-grade recommended) and thickness specifications.

- Review budget against long-term durability and cost-effectiveness.

By thoroughly evaluating these critical factors, your business can confidently select a stainless steel corner bench that meets operational needs, adheres strictly to FSANZ regulations, and delivers long-term profitability and satisfaction.

Case Study: Real Results from Implementing Stainless Steel Corner Benches at Café Aroma, Sydney

Café Aroma, a bustling café in Sydney’s CBD, provides a compelling corner bench real case study, showcasing how strategic kitchen layout changes can dramatically enhance kitchen performance, hygiene, and staff morale.

Initial Challenges: Limited Space and Hygiene Issues

Before renovation, Café Aroma faced considerable kitchen constraints. Limited counter space resulted in overcrowded work areas, making staff movements difficult during peak hours. Moreover, cleaning efficiency was compromised, and the café struggled to maintain hygiene standards, receiving repeated negative feedback from council hygiene inspections due to difficult-to-clean spaces and inadequate storage solutions.

Solution Implemented: Installation of Stainless Steel Corner Benches

After consulting with KW Commercial, Café Aroma installed two stainless steel corner benches strategically positioned between their sink bench and dishwasher area. These benches maximised previously unused corners, providing additional workspace and creating a smooth, hygienic workflow. Their durable stainless steel surfaces improved daily cleaning routines significantly, ensuring effortless compliance with FSANZ regulations.

Measurable Outcomes: Efficiency, Hygiene, and Staff Satisfaction

Six months following installation, Café Aroma observed substantial improvements:

- Increased Efficiency: Kitchen workflow improved by approximately 30%, as measured by reduced meal prep times and faster cleaning processes.

- Improved Hygiene Scores: Council hygiene inspections resulted in consistently high scores post-renovation, eliminating previous penalties related to cleanliness issues.

- Positive Staff Feedback: Kitchen staff reported significantly reduced fatigue and stress levels, citing smoother operations and better-organised workspaces.

Customer Testimonial:

“Investing in stainless steel corner benches transformed our kitchen. The extra space and improved cleanliness meant faster service and happier staff. Best decision we’ve made for our business.” – Marcus Lee, Owner, Café Aroma, Sydney

Café Aroma’s experience clearly demonstrates how carefully chosen successful kitchen corner solutions deliver real, measurable improvements in operational efficiency, compliance, and staff morale, confirming that stainless steel benches offer genuine value and lasting stainless steel bench real results for commercial kitchens.

Frequently Asked Questions (FAQ) about Stainless Steel Corner Benches

1. Are stainless steel corner benches worth the investment for small kitchens?

Absolutely. Stainless steel corner benches maximise limited space in small commercial kitchens, improving workflow efficiency and enhancing hygiene compliance, making them an ideal investment.

2. What grade of stainless steel is best for commercial corner benches?

304-grade stainless steel is highly recommended for Australian commercial kitchens. It’s durable, corrosion-resistant, food-safe, and fully compliant with FSANZ hygiene standards.

3. How do you properly clean stainless steel corner benches?

Use mild detergent and warm water daily, dry immediately to avoid water spots. Weekly, use stainless steel-specific cleaners and polish with a soft cloth, always wiping along the grain to prevent scratches.

4. Can a stainless steel corner bench integrate easily with existing kitchen equipment?

Yes. Stainless steel corner benches are designed for seamless integration with sink benches, dishwashers, and standard workbenches, enhancing kitchen functionality and workflow efficiency.

5. Where should I position a stainless steel corner bench in my kitchen?

Ideally, place your corner bench adjacent to sink or dishwasher areas, or integrate it between prep stations and cooking equipment. Strategic placement significantly boosts kitchen productivity.

Conclusion: Enhance Your Kitchen Efficiency with Stainless Steel Corner Benches

Investing in stainless steel corner benches is a strategic move for any commercial kitchen aiming to maximise space utilisation, ensure hygiene compliance, and elevate professional aesthetics. These benches not only solve practical kitchen challenges but also directly contribute to your bottom line by improving workflow efficiency and reducing long-term operational costs.

Choosing stainless steel corner benches ensures your kitchen adheres seamlessly to Australia’s strict FSANZ hygiene regulations, enhances customer confidence, and boosts staff productivity and morale. With their sleek, professional appearance, these benches also significantly uplift your kitchen’s overall image and operational effectiveness.

Take the next step toward optimising your commercial kitchen today. Explore our comprehensive range of premium Stainless Steel Corner Benches, or contact KW Commercial to discuss customised solutions perfectly suited for your business needs.